| Aspect | Jigs | Fixtures |

|---|---|---|

| Purpose and Function | Primarily used for guiding tools during machining, such as drilling, reaming, or shaping. | Primarily designed to hold and secure workpieces in a fixed position during operations. |

| Design and Configuration | Typically have complex designs with guiding components like bushings, templates, or guiding elements. | Often feature simpler designs with a focus on clamping and supporting workpieces. |

| Customization | Custom-made for specific operations and workpiece geometries. | Tailored to accommodate workpiece variations but may lack the precision of jigs for specific tasks. |

| Adaptability and Versatility | Less adaptable to different tasks; designed for specific operations. | More adaptable to various workpiece sizes, shapes, and types; versatile for accommodating changes. |

| Applications and Industries | Commonly used in applications demanding high precision and repeatability, such as aerospace, automotive, and electronics manufacturing. | Employed in various industries, including metalworking, woodworking, plastics, and general manufacturing, where workpiece variation is common. |

The manufacturing world is a vibrant and dynamic landscape, where precision and efficiency are the keys to success. Understanding the nuances of jigs and fixtures is like unlocking the secrets to achieving consistency and accuracy in your production processes. These tools are like the unsung heroes working tirelessly behind the scenes to ensure every workpiece you produce is a masterpiece of precision.

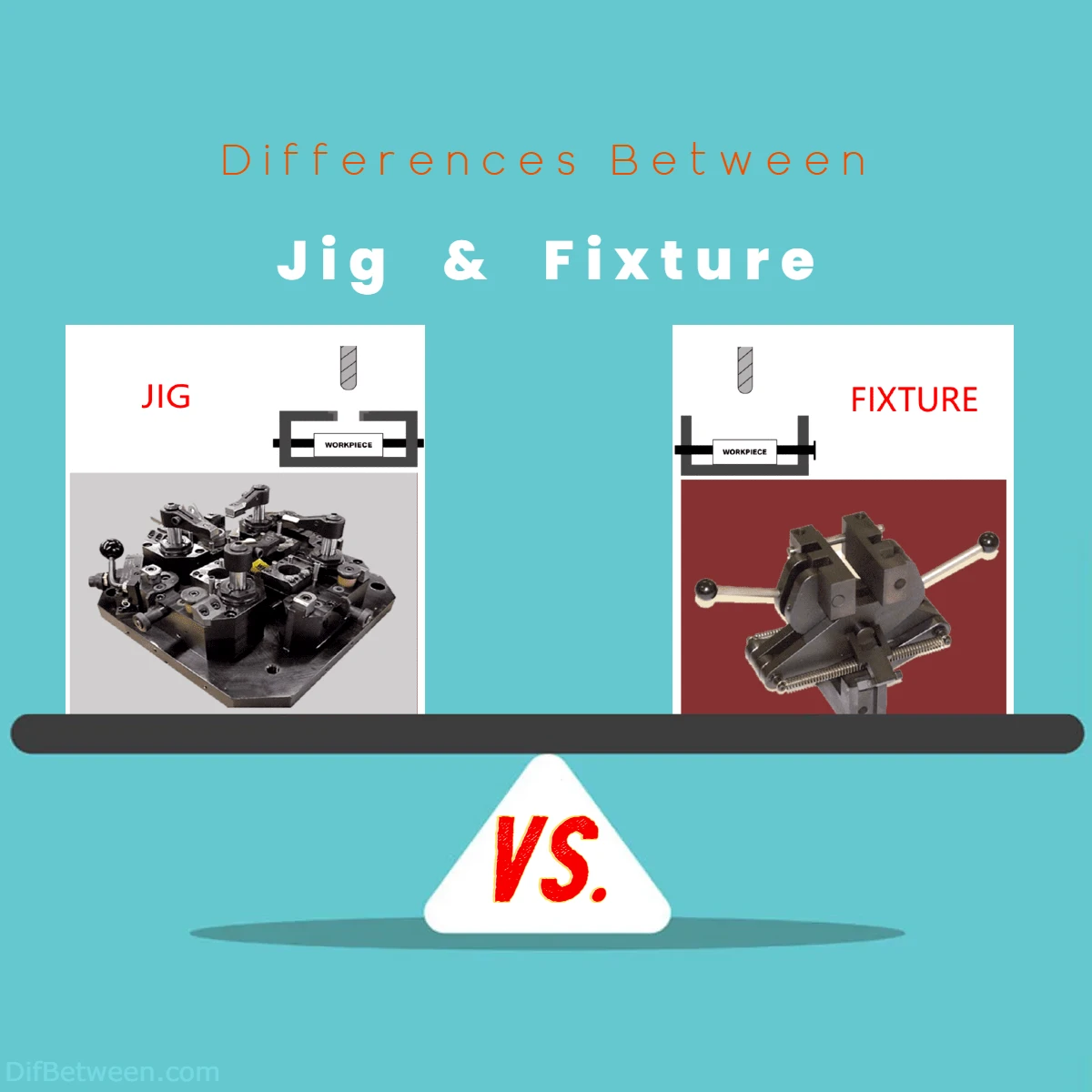

Differences Between Jig and Fixture

The main differences between Jig vs Fixture lie in their respective functions and designs. Jigs are primarily utilized for guiding tools during machining processes, ensuring precise and repeatable results, making them ideal for drilling and reaming tasks. On the other hand, Fixtures are designed to securely hold workpieces in place, maintaining their orientation during operations such as milling and welding. Additionally, jigs often feature intricate guiding components, while fixtures have simpler designs with a primary focus on workpiece clamping and support. These distinctions make it crucial to select the right tool based on the specific requirements of a manufacturing project, whether it demands high precision (jigs) or adaptability to varied workpieces (fixtures).

Understanding Jigs and Fixtures

The Fundamentals of Jigs

Jigs, often referred to as workholding jigs, are specialized tools designed to assist in the precise and repeatable positioning of a workpiece during machining, assembly, or inspection. They are like guiding hands that ensure a component is held firmly and accurately in place, allowing for consistent and error-free processing.

Key Characteristics of Jigs:

- Guidance: Jigs guide the cutting tool or machine to follow a specific path, ensuring accuracy.

- Repeatability: They enable the production of identical workpieces with high precision.

- Customization: Jigs can be tailored to suit the geometry and requirements of a particular workpiece.

- Workpiece Clamping: Jigs secure the workpiece, preventing movement or vibration during operations.

Typically, jigs find their applications in processes such as drilling, reaming, tapping, and welding, where precision is paramount. Let’s take an example to understand better: imagine a jig that holds a metal sheet in place while holes are drilled for fasteners. This jig ensures that each hole is in the exact position every time, guaranteeing a perfect fit for the fasteners.

The Essence of Fixtures

Fixtures, on the other hand, are complementary tools in the world of manufacturing. They are designed to hold a workpiece in place, but their primary function differs from that of jigs. Fixtures focus on maintaining the orientation and position of the workpiece, rather than guiding the cutting or shaping tool.

Key Characteristics of Fixtures:

- Positioning: Fixtures primarily position and support the workpiece during machining or assembly.

- Consistency: They ensure the workpiece is consistently located in the correct orientation.

- Repeatability: Fixtures contribute to producing uniform and precise parts.

- Stability: Fixtures are known for their robust clamping and support systems.

Consider an example where you need to mill a series of identical metal parts with complex contours. A fixture is the tool of choice here, as it holds the workpiece securely and consistently while the milling machine shapes it to perfection.

Now that we’ve grasped the basics of jigs and fixtures, let’s delve deeper into their differences and understand when to employ each of these tools.

Key Differences Between Jigs and Fixtures

Jigs and fixtures, while serving similar purposes in manufacturing, have distinct characteristics that set them apart. To help you distinguish between these two tools, let’s explore four key aspects where they differ.

Purpose and Function

Jigs: Jigs are primarily used for guiding the tool during machining processes. Their main function is to ensure that the tool follows a specific path, making them ideal for drilling, reaming, and other precision operations. Jigs contribute to the accuracy and repeatability of the workpiece.

Fixtures: Fixtures, in contrast, are focused on holding the workpiece securely and maintaining its position. They do not guide the tool but rather provide stability and consistency during operations like milling, grinding, or welding. Fixtures are all about ensuring that the workpiece remains in the correct orientation throughout the process.

In summary, jigs guide the tool, while fixtures hold and support the workpiece.

Design and Configuration

Jigs: Jigs are typically more complex in design, featuring components that guide and control the tool’s movement. They often have bushings, templates, or other guiding elements that precisely direct the tool’s path. Jigs are custom-made for specific operations and workpiece geometries.

Fixtures: Fixtures have a simpler design in comparison to jigs. They focus on clamping and supporting the workpiece, and their design aims to minimize any interference with the machining process. Fixtures are also tailored to accommodate the workpiece, but their design is more straightforward.

The table below summarizes the differences in design between jigs and fixtures:

| Aspect | Jigs | Fixtures |

|---|---|---|

| Complexity | More complex design | Simpler design |

| Guiding Elements | Include guiding components | Primarily clamping and support features |

| Customization | Custom-made for specific operations | Tailored to accommodate workpiece |

Adjustability and Versatility

Jigs: Jigs are less versatile when it comes to accommodating different workpieces. They are usually designed for a specific operation and workpiece geometry. While they offer high precision for that specific task, they may not be easily adaptable to other operations.

Fixtures: Fixtures are more adjustable and versatile. They can often be adapted for different workpieces by making simple changes to the clamping mechanisms. Fixtures excel in scenarios where multiple workpieces with varying geometries need to be processed.

The following table summarizes the differences in adjustability and versatility between jigs and fixtures:

| Aspect | Jigs | Fixtures |

|---|---|---|

| Adaptability | Less adaptable to different tasks | More adaptable to various workpieces |

| Versatility | Designed for specific operations | Versatile for accommodating changes |

Applications and Industries

Jigs: Jigs are predominantly used in applications that require high precision and repeatability. Some common industries where jigs find extensive use include aerospace, automotive, and electronics manufacturing. They are indispensable in tasks like drilling holes for aircraft components or creating precise connections in electronics.

Fixtures: Fixtures are versatile tools used in various industries, such as metalworking, woodworking, and plastics manufacturing. They are essential in tasks like milling metal parts, shaping wood, or welding assemblies. The ability to securely hold workpieces of varying shapes and sizes makes fixtures valuable in a wide range of applications.

In the table below, you can see a summary of the primary industries and applications where jigs and fixtures are commonly employed:

| Aspect | Jigs | Fixtures |

|---|---|---|

| Industries | Aerospace, automotive, | Metalworking, woodworking, |

| electronics, precision | plastics, general | |

| engineering | manufacturing | |

| Applications | Drilling, reaming, precise | Milling, grinding, welding, |

| connections, intricate | assembly, machining of | |

| components | complex workpieces |

With these key differences in mind, you can better appreciate when to use jigs and when to opt for fixtures in your manufacturing processes. The choice between these tools should be based on the specific requirements of your project and the level of precision and adaptability needed.

Advantages and Disadvantages

Understanding the pros and cons of both jigs and fixtures is essential for making informed decisions in manufacturing. Each tool offers a unique set of advantages and has its share of limitations. Let’s explore the benefits and drawbacks of both jigs and fixtures.

The Pros and Cons of Jigs

Advantages of Jigs:

- Precision: Jigs excel in guiding tools with unmatched precision, ensuring accurate and repeatable results.

- Repeatability: They enable the production of numerous identical workpieces, which is crucial for maintaining product consistency.

- Customization: Jigs can be tailored to suit the specific geometry of the workpiece and the operation being performed.

- Enhanced Safety: The guidance provided by jigs minimizes the risk of errors, reducing the chance of accidents or damage to workpieces.

Disadvantages of Jigs:

- Limited Versatility: Jigs are designed for specific tasks and may not be easily adaptable to different operations.

- Higher Setup Time: Creating and setting up a jig can be time-consuming, especially when dealing with intricate workpiece geometries.

- Cost: Custom-made jigs can be expensive, making them less cost-effective for small-scale or varied production.

The Pros and Cons of Fixtures

Advantages of Fixtures:

- Versatility: Fixtures are adaptable and can accommodate a range of workpieces, making them suitable for diverse production needs.

- Time Efficiency: They are quick to set up and change between workpieces, reducing downtime in the manufacturing process.

- Cost-Effective: Fixtures are often more cost-effective, especially when the same fixture can be used for multiple workpiece types.

- Consistency: Fixtures provide stable support, reducing the chances of errors and improving the quality of the end product.

Disadvantages of Fixtures:

- Lower Precision: Fixtures do not guide the tool as precisely as jigs, which may be a limitation in operations requiring extremely high accuracy.

- Less Customization: While fixtures are versatile, they may not offer the same level of customization as jigs for highly specialized tasks.

- Complex Workpieces: Complex or irregularly shaped workpieces may pose challenges in fixture design and setup.

Now that we’ve examined the advantages and disadvantages of both jigs and fixtures, you can weigh these factors against your specific manufacturing needs and constraints when making a choice.

Selecting the Right Tool for the Job

The decision to use a jig or a fixture in a manufacturing process hinges on a variety of factors. To help you make an informed choice, consider the following key considerations and real-life examples where these tools play a pivotal role.

Factors to Consider

- Precision Requirements: If your project demands the utmost precision and repeatability, especially in tasks like drilling or reaming, a jig is the way to go.

- Production Volume: For high-volume production of identical components, where consistency is key, jigs are the preferred choice.

- Workpiece Variation: If your workpieces vary in size, shape, or dimensions, fixtures are more adaptable and cost-effective.

- Set-Up Time: Consider the time it takes to create and set up the tool. Fixtures typically have quicker setup times and are more suitable for rapid workpiece changes.

- Cost Constraints: Evaluate your budget. Jigs can be costly to design and build, while fixtures are often a more economical option.

Real-Life Examples

Let’s delve into some real-world scenarios where the choice between jigs and fixtures is crucial.

Example 1: Aircraft Manufacturing

In the aerospace industry, precision and consistency are paramount. When drilling holes for critical components like engine mounts or wing attachments, jigs are indispensable. They ensure that each hole is positioned with absolute accuracy, guaranteeing the structural integrity of the aircraft.

Example 2: Woodworking Workshop

In a woodworking workshop where artisans create custom furniture, fixtures shine. Woodworkers often deal with various workpiece shapes and sizes. A well-designed fixture that securely holds different pieces during routing, shaping, or sanding processes streamlines production while maintaining quality.

Example 3: Automotive Production

In automobile assembly lines, fixtures play a pivotal role. They hold car body parts in place during welding processes. The ability to adapt quickly to different car models and body types makes fixtures a cost-effective choice for mass production.

Example 4: Jewelry Manufacturing

Creating intricate, custom jewelry pieces requires precision and attention to detail. Jigs are the go-to tools for jewelers when setting gemstones, ensuring that each piece is meticulously crafted with precision.

In each of these examples, the choice between jigs and fixtures is driven by the specific needs of the industry and the type of workpiece being processed. Understanding the nuances of your manufacturing operation is key to selecting the right tool for the job.

Beyond the Basics: Advanced Jig Applications

While we’ve covered the fundamentals of jigs and their primary applications, it’s important to recognize that these versatile tools have found their way into some advanced and specialized applications. Let’s explore a few of these advanced use cases.

Welding Jigs for Aerospace Manufacturing

In the aerospace industry, where the integrity of aircraft components is of utmost importance, welding jigs play a vital role. These specialized jigs are designed to precisely position and secure components during the welding process. By maintaining strict tolerances, they ensure that critical components like engine mounts, landing gear, and structural elements are fabricated to the highest standards. The use of welding jigs reduces the risk of errors and contributes to the structural integrity and safety of aircraft.

PCB Assembly Jigs for Electronics Manufacturing

In electronics manufacturing, the assembly of printed circuit boards (PCBs) requires pinpoint accuracy. PCB assembly jigs are designed to hold and guide the PCB and its components during the soldering process. These jigs ensure that components are precisely aligned and soldered in the correct locations. With the shrinking size of electronic components and the demand for miniaturization, PCB assembly jigs have become increasingly sophisticated, featuring fine-pitch component alignment and advanced inspection capabilities.

Medical Device Manufacturing Jigs

The production of medical devices demands uncompromising precision. Jigs are extensively used in the manufacturing of items like surgical instruments, implants, and diagnostic devices. For instance, in the production of orthopedic implants, jigs are employed to ensure the precise shaping and machining of materials like titanium and stainless steel. The accuracy of these jigs is instrumental in the successful integration of medical devices within the human body.

Innovations in Fixture Technology

In the world of fixtures, innovations have been steadily reshaping how they are used and their capabilities. Let’s explore some recent developments in fixture technology.

Modular Fixtures

Modular fixtures are designed for adaptability and reconfiguration. They consist of standardized components that can be easily assembled or disassembled to accommodate various workpiece geometries. These fixtures save time and resources in production environments with frequent workpiece changes. Modular fixtures are equipped with quick-change mechanisms, reducing downtime and increasing efficiency.

Magnetic Work holding Fixtures

Magnetic work holding fixtures have gained popularity for their ability to securely hold ferrous workpieces without the need for clamps or other mechanical fasteners. The magnetic force provides a reliable grip while allowing for easy setup and changeovers. These fixtures are particularly useful in applications like grinding and milling, where workpiece stability is crucial.

3D Printing of Fixtures

The advent of 3D printing technology has opened new horizons for fixture design. Manufacturers can now rapidly prototype and produce custom fixtures on-demand. 3D-printed fixtures are lightweight, cost-effective, and can be intricately designed to suit the specific requirements of a given task. This innovation has made fixtures more accessible and adaptable for smaller-scale manufacturing operations.

Compliance and Safety Considerations

Meeting Industry Standards with Jigs and Fixtures

In the manufacturing world, adhering to industry standards and regulations is non-negotiable. Jigs and fixtures, as integral components of manufacturing processes, must also meet certain standards to ensure product quality and safety. Let’s delve into the significance of compliance and standards in the realm of jigs and fixtures.

ISO 9001 and Quality Management

ISO 9001 is an internationally recognized quality management system standard. Manufacturers who implement ISO 9001 strive to meet specific quality and regulatory requirements. Jigs and fixtures, being instrumental in maintaining product quality, must conform to these standards. This means ensuring that they are designed, maintained, and used in a manner that consistently meets quality requirements.

Safety Standards

Manufacturing processes can involve inherent risks, especially when heavy machinery is involved. Jigs and fixtures should adhere to safety standards and best practices to protect workers and maintain a safe workplace. Ensuring that jigs and fixtures are designed to prevent accidents, such as workpiece ejections or tooling malfunctions, is essential.

Tolerance and Metrology Standards

Jigs and fixtures are used to achieve precision and maintain tight tolerances. Conformance to metrology standards is crucial to ensure that jigs and fixtures are capable of accurately holding and guiding workpieces. This involves rigorous calibration, regular inspection, and adherence to measurement standards, such as those defined by the National Institute of Standards and Technology (NIST).

Ensuring Workplace Safety

The safety of workers in manufacturing environments is a top priority. Jigs and fixtures, being part of the manufacturing process, can influence workplace safety. Here are some measures to ensure the safe use of jigs and fixtures:

Regular Maintenance

Periodic maintenance is essential to keep jigs and fixtures in optimal condition. Routine checks should be conducted to identify wear and tear, and any damaged or worn-out components should be replaced promptly.

Training and Education

Workers should receive comprehensive training on the proper use of jigs and fixtures. This training should encompass safety protocols, workpiece handling, and the correct setup and operation of these tools.

Hazard Mitigation

Jigs and fixtures should be designed with safety in mind. Features like interlocks, emergency stop mechanisms, and protective enclosures can mitigate potential hazards.

Ergonomics

Consider the ergonomics of the work environment. Ensure that workers can easily and safely access jigs and fixtures without straining or putting themselves at risk of injury.

By integrating compliance with industry standards and safety measures into your manufacturing processes, you not only ensure the quality of your products but also safeguard the well-being of your workforce.

The Future of Jigs and Fixtures

Emerging Technologies and Industry 4.0

As the manufacturing landscape evolves, so do the roles of jigs and fixtures. Emerging technologies and the principles of Industry 4.0 are reshaping the way these tools are used and integrated into modern production processes.

Automation and Robotics

Industry 4.0 emphasizes automation and data exchange in manufacturing. Jigs and fixtures are being integrated with robotic systems to enable more precise and efficient handling of workpieces. Robotic arms equipped with advanced vision systems can work in tandem with jigs and fixtures to optimize processes.

Digital Twins and Simulation

The concept of digital twins, where virtual representations of physical objects are created, is being applied to jigs and fixtures. This allows manufacturers to simulate and optimize their processes before physical implementation. Digital twins of jigs and fixtures enable more accurate predictions of tooling performance.

IoT and Smart Fixtures

The Internet of Things (IoT) is making its way into the manufacturing world. Smart fixtures equipped with sensors can provide real-time data on workpiece positioning, clamping forces, and tool wear. This data is invaluable for quality control and predictive maintenance.

Sustainability and Green Manufacturing

In an era where sustainability is paramount, jigs and fixtures are also evolving to align with green manufacturing practices.

Eco-Friendly Materials

Manufacturers are increasingly using eco-friendly materials in the construction of jigs and fixtures. This reduces the environmental impact and aligns with sustainability goals.

Resource Efficiency

Optimizing the design and use of jigs and fixtures to minimize material waste is a key consideration. Precision and repeatability are essential for reducing scrap and rework.

Energy Efficiency

Efforts are being made to design fixtures that are energy-efficient. This includes the use of efficient clamping mechanisms and reduced power consumption in fixture-related processes.

Recycling and Circular Economy

The end-of-life phase of jigs and fixtures is also being addressed. Manufacturers are exploring recycling and repurposing options to contribute to a circular economy.

The future of jigs and fixtures is undeniably linked to technological advancements and sustainability efforts. These tools are evolving to meet the demands of modern manufacturing, where precision, efficiency, and eco-conscious practices are key drivers.

Jig or Fixture : Which One is Right Choose for You?

Choosing between a jig and a fixture in your manufacturing process can be a pivotal decision. Each tool has its unique strengths and applications, and the right choice depends on your specific needs and constraints. In this guide, we will help you navigate this decision-making process by exploring the key considerations that will guide you to the most suitable tool for your project.

Factors to Consider

Before making the choice between a jig and a fixture, consider the following factors:

Precision Requirements

Jig: If your project demands pinpoint precision and repeatability, especially in tasks like drilling, reaming, or machining, a jig is the tool to choose. Jigs are designed to guide the tool with unmatched accuracy, ensuring consistent results.

Fixture: Fixtures are generally used to maintain the position and orientation of workpieces. While they provide stability, they may not guide the tool as precisely as jigs. Consider whether the application requires the highest level of precision.

Production Volume

Jig: If you are involved in high-volume production of identical components, where maintaining consistency is a primary concern, jigs are your go-to tool. Jigs excel in ensuring that every workpiece is produced with the same level of precision.

Fixture: For lower volume production runs or projects with a variety of workpiece shapes and sizes, fixtures may offer more flexibility. Their adaptability to different workpieces can be a time-saving and cost-effective solution.

Workpiece Variation

Jig: Jigs are often designed for specific tasks and workpiece geometries. They may not be easily adaptable to different operations or workpiece variations. Consider whether your project involves a consistent workpiece geometry or varying shapes and sizes.

Fixture: Fixtures are known for their versatility and adaptability. If your workpieces differ in shape, size, or dimensions, fixtures can be adjusted to accommodate these variations. They are particularly useful in situations where workpiece diversity is a constant challenge.

Set-Up Time

Jig: Creating and setting up a jig can be a time-consuming process, especially when dealing with intricate workpiece geometries. Assess whether your project allows for the time required to design and set up a jig.

Fixture: Fixtures are generally quicker to set up and change between workpieces, reducing downtime in the manufacturing process. If rapid workpiece changes are a common occurrence in your production environment, fixtures may be the more efficient choice.

Cost Constraints

Jig: Custom-made jigs can be expensive, especially when designed for highly specialized tasks. Consider your budget and whether it allows for the investment in custom jigs.

Fixture: Fixtures are often more cost-effective, especially when the same fixture can be adapted for multiple workpiece types. If cost is a primary concern, fixtures may be the economical choice.

Real-Life Examples

To better understand how the choice between jigs and fixtures plays out in real-world scenarios, let’s explore a few examples from different industries:

Aerospace Manufacturing

In the aerospace industry, where precision and consistency are paramount, jigs are indispensable. They are used for tasks like drilling holes for critical components, ensuring that each hole is positioned with absolute accuracy to guarantee the structural integrity of the aircraft.

Woodworking Workshop

In a woodworking workshop where artisans create custom furniture, fixtures shine. Woodworkers often deal with various workpiece shapes and sizes. A well-designed fixture that securely holds different pieces during routing, shaping, or sanding processes streamlines production while maintaining quality.

Automotive Production

In automobile assembly lines, fixtures play a pivotal role. They hold car body parts in place during welding processes, allowing for quick adaptability to different car models and body types. This makes fixtures a cost-effective choice for mass production in the automotive industry.

Jewelry Manufacturing

Creating intricate, custom jewelry pieces requires precision and attention to detail. Jigs are the go-to tools for jewelers when setting gemstones, ensuring that each piece is meticulously crafted with precision.

In each of these examples, the choice between jigs and fixtures is driven by the specific needs of the industry and the type of workpiece being processed. Understanding the nuances of your manufacturing operation is key to selecting the right tool for the job.

In Conclusion

The choice between a jig and a fixture is not a one-size-fits-all decision. It depends on a multitude of factors, including your precision requirements, production volume, workpiece variation, setup time, and budget constraints. By carefully considering these factors and assessing your specific project, you can make an informed choice that optimizes your manufacturing process.

FAQs

Jigs are primarily designed to guide tools during machining processes, ensuring precision and repeatability.

Fixtures are primarily used to securely hold workpieces in place during operations and maintain their orientation, but they do not guide the tools like jigs.

Fixtures are generally more adaptable to various workpiece sizes, shapes, and types, making them suitable for situations with workpiece variation.

Jigs are the preferred choice when precision and repeatability are crucial, and the project demands guiding the tool with high accuracy.

Jigs find extensive use in industries such as aerospace, automotive, and electronics manufacturing, where high precision is essential.

Yes, fixtures are versatile tools and can be employed in woodworking workshops where workpiece variation is common.

Jigs often have complex designs with guiding components, while fixtures have simpler designs with a focus on clamping and supporting workpieces.

Fixtures are often more cost-effective, especially when the same fixture can be adapted for multiple workpiece types, making them a great choice for variable workpieces.

The choice between a jig and a fixture should be based on factors like precision requirements, production volume, workpiece variation, setup time, and budget constraints. Evaluate these aspects to make an informed decision that suits your specific project.

Yes, ensuring the safety of workers is crucial. Regular maintenance, worker training, hazard mitigation, and ergonomic considerations should be part of your safety measures when using these tools.

Read More: