| Aspect | Steam Engine | Steam Turbine |

|---|---|---|

| Design | Reciprocating motion with a piston-cylinder arrangement | Rotary motion with a rotor and blades |

| Operating Speed | Operate at lower speeds due to reciprocating motion | Operate at higher speeds due to rotary motion |

| Starting and Stopping | Can start and stop relatively quickly | Not well-suited for frequent starting and stopping |

| Mechanical Stress | Experience more mechanical stress and may require more maintenance | Experience less mechanical stress, resulting in reduced maintenance requirements |

| Efficiency | Lower efficiency due to energy losses from reciprocating motion | High efficiency, with minimal energy losses due to rotary motion |

| Power Output | Suitable for applications where high power output is not a primary concern | Ideal for high-power applications, such as electricity generation and large ship propulsion |

| Applications | Found in heritage railways, antique machinery, and smaller, specialty applications | Prevalent in power generation, marine propulsion, and heavy industries like oil and gas |

| Environmental Impact | May have higher emissions and fuel consumption due to lower efficiency | Generally more environmentally friendly due to higher efficiency and lower emissions |

| Versatility | Versatile and adaptable to a wide range of applications, particularly in niche or specialty uses | Not as versatile and best suited for continuous, high-demand operations |

| Historical Significance | Valued for their historical significance and aesthetics | May not have the same historical significance, but have a strong presence in modern industries |

| Future Prospects | Finding renewed interest in combined heat and power (CHP) systems | Integral to electricity generation with ongoing advancements in efficiency and sustainability |

Steam engines, with their piston-cylinder dance and rich historical tapestry, evoke images of the Industrial Revolution and the birth of modern industry. Meanwhile, steam turbines, with their elegant rotary motion and high-efficiency grace, dominate power generation and propel colossal ships across the seas.

Differences Between Steam Engine and Steam Turbine

The main differences between a Steam Engine and a Steam Turbine lie in their design, operation, and applications. Steam engines utilize reciprocating motion with a piston-cylinder arrangement, suitable for versatile, low-power applications, with their historical significance adding to their appeal. In contrast, Steam Turbines employ rotary motion with a rotor and blades, excelling in high-power, high-efficiency applications like electricity generation and large-scale propulsion. These differences extend to operational characteristics, mechanical stress, and environmental impact, making it essential to choose the right technology based on specific needs and priorities.

Introduction to Steam Power

Steam Engines

Steam engines are often considered the precursors of modern steam technology. They rely on the principles of converting heat energy from steam into mechanical work. These iconic devices played a critical role in the Industrial Revolution, revolutionizing transportation, manufacturing, and more.

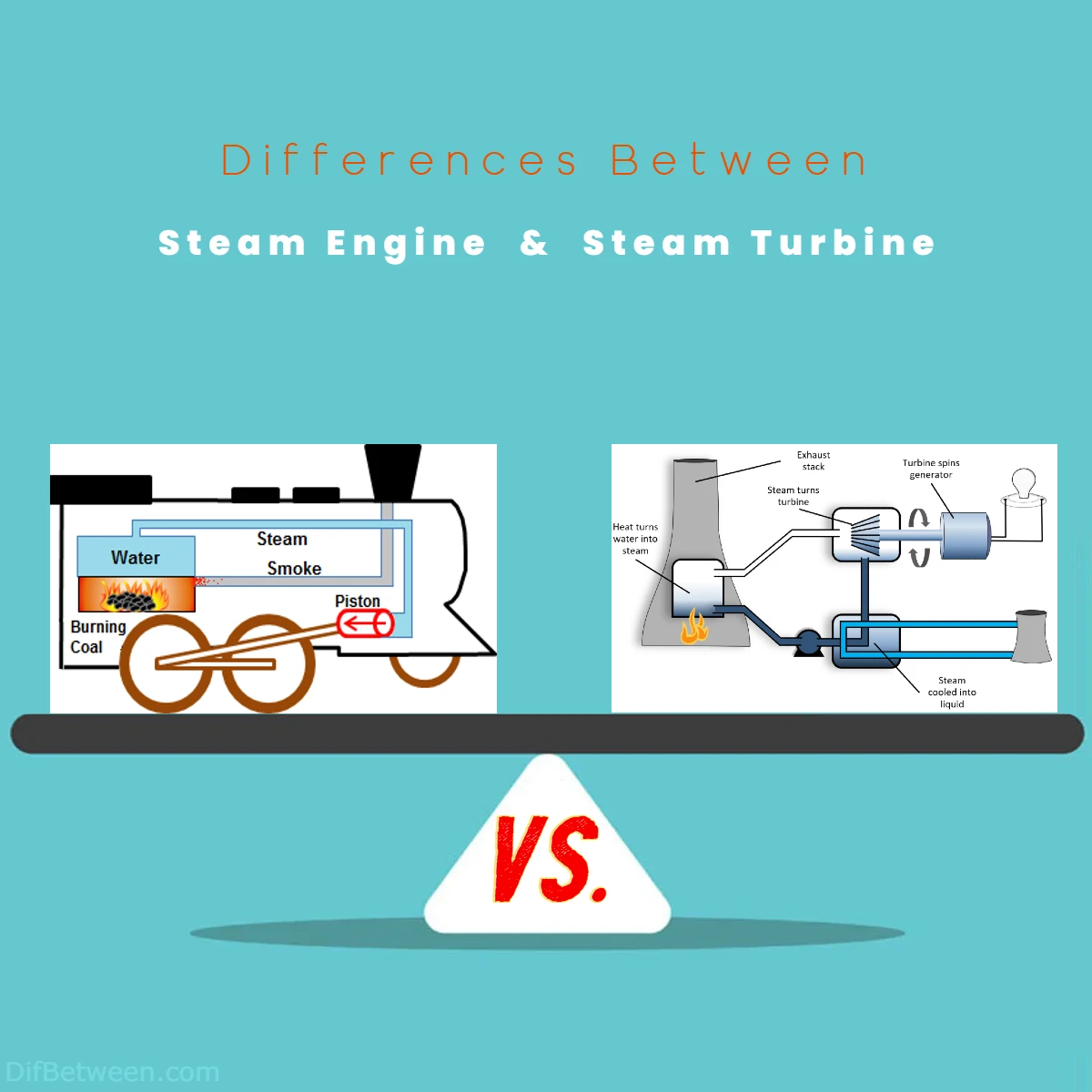

Steam engines are typically characterized by a piston-cylinder arrangement. When steam is introduced into the cylinder, it expands, forcing the piston to move. This reciprocating motion is then harnessed to perform various tasks, from propelling locomotives and ships to driving machinery in factories.

Steam Turbines

Steam turbines, on the other hand, represent a more advanced and efficient technology in the world of steam power. These machines are designed to convert thermal energy from high-pressure steam into rotary motion, which can be used to generate electricity, power ships, or drive industrial processes.

Unlike steam engines, which operate on the principle of reciprocating motion, steam turbines employ rotary motion. As high-pressure steam flows over a series of blades mounted on a shaft, it causes the shaft to spin, producing mechanical work.

Design and Operation

Steam Engines

Design: Steam engines are characterized by a simple and robust design. They typically consist of a boiler to generate steam, a cylinder with a piston, and a crankshaft. The steam is supplied to the cylinder, where it expands and pushes the piston back and forth. The reciprocating motion of the piston is then transferred to the crankshaft, which can be connected to a variety of mechanical systems.

Operation: The operation of a steam engine involves several stages:

- Steam Generation: Water is heated in a boiler to produce high-pressure steam.

- Steam Supply: The high-pressure steam is directed into the cylinder.

- Expansion: The steam expands within the cylinder, pushing the piston.

- Exhaust: Steam is exhausted from the cylinder to a condenser, where it is condensed back into water.

- Repeat: The cycle is repeated continuously to maintain power output.

Steam Turbines

Design: Steam turbines have a more complex design compared to steam engines. They consist of a rotor with multiple blades and stationary nozzles. The rotor is mounted on a shaft, and the steam is directed through the nozzles onto the rotor blades. This design allows for the conversion of high-pressure steam into rotary motion.

Operation: The operation of a steam turbine can be summarized as follows:

- Steam Supply: High-pressure steam is supplied to the turbine.

- Expansion: Steam flows over the blades of the rotor, causing it to spin.

- Work Output: The rotary motion of the shaft is used to drive generators, propellers, or other mechanical systems.

- Exhaust: Steam exits the turbine and may be condensed or returned to the boiler for reheating.

- Continuous Operation: Steam turbines operate continuously to produce mechanical or electrical power.

Efficiency and Power Output

Steam Engines

Efficiency: Steam engines are known for their relatively lower efficiency compared to steam turbines. The reciprocating motion of the piston leads to energy losses due to friction and heat dissipation. This makes them less efficient in converting thermal energy into mechanical work.

Power Output: The power output of steam engines varies widely depending on their size and design. Smaller steam engines may produce several horsepower, while larger ones can generate thousands of horsepower. Steam engines are suitable for a wide range of applications, from small-scale machinery to locomotives and ships.

Steam Turbines

Efficiency: Steam turbines are renowned for their high efficiency. The rotary motion and streamlined design result in minimal energy losses, making them incredibly efficient in converting thermal energy into mechanical work. Steam turbines are commonly used in power generation, where efficiency is paramount.

Power Output: Steam turbines are capable of producing a vast amount of power. They are widely used in power plants to generate electricity, and large marine steam turbines can produce tens of thousands of horsepower to propel massive ships. The power output of steam turbines is tailored to meet the demands of various industries.

Applications and Industries

Steam Engines

Applications: Steam engines have a rich history of applications, including:

- Early locomotives: Steam engines were used to power the first steam locomotives, enabling the expansion of railways and transportation.

- Industrial machinery: They drove machinery in factories, contributing to the growth of manufacturing during the Industrial Revolution.

- Ships: Steam engines were employed in ships, enabling them to navigate long distances without relying on wind or muscle power.

- Pumping stations: Steam engines were used for water pumping, draining marshes, and controlling water levels in mines.

Industries: The influence of steam engines was felt across various industries, especially during the 18th and 19th centuries. They played a vital role in the development of transportation, manufacturing, and mining.

Steam Turbines

Applications: Steam turbines find applications in several modern industries, including:

- Power generation: Steam turbines are the heart of many power plants, where they produce electricity from steam.

- Marine propulsion: Large steam turbines propel ships and submarines, providing efficient means of propulsion.

- Oil and gas industry: Steam turbines drive compressors and generators in the extraction and processing of hydrocarbons.

- Process industries: Steam turbines are used in various industrial processes, such as sugar refining and chemical manufacturing.

Industries: Steam turbines are essential to the power generation sector, ensuring a stable supply of electricity for homes and industries. They are also vital in the maritime industry, where they enable the efficient operation of ships and submarines. Moreover, the oil and gas industry relies on steam turbines for various applications, from drilling to refining.

Advantages and Disadvantages

Steam Engines

Advantages:

- Simplicity: Steam engines have a straightforward design, making them easier to understand and maintain.

- Versatility: They can be adapted to different applications, from locomotives to factory machinery.

- Historical Significance: Steam engines played a pivotal role in the Industrial Revolution and the development of modern industry.

Disadvantages:

- Lower Efficiency: They are less efficient than steam turbines, leading to higher fuel consumption for a given power output.

- Limited Power Output: Steam engines may not be suitable for high-power applications like electricity generation.

- Maintenance Intensive: They require regular maintenance due to wear and tear of moving parts.

Steam Turbines

Advantages:

- High Efficiency: Steam turbines are renowned for their efficiency, resulting in lower fuel consumption and reduced emissions.

- High Power Output: They are capable of producing a vast amount of power, making them ideal for electricity generation and large ships.

- Low Maintenance: Steam turbines have fewer moving parts, leading to lower maintenance requirements.

Disadvantages:

- Complex Design: Their design and operation can be complex, requiring specialized knowledge for maintenance and repair.

- Limited Versatility: Steam turbines are primarily suited for high-power applications and may not be adaptable to smaller-scale uses.

- Initial Cost: The construction and installation of steam turbines can be expensive.

Historical Context

Steam Engines

Steam engines have a rich historical context, often associated with the Industrial Revolution of the 18th and 19th centuries. They were instrumental in transforming various industries and transportation systems. Steam engines powered the first locomotives, enabling the rapid expansion of railways, and played a crucial role in the growth of manufacturing by driving machinery in factories. Moreover, steam engines revolutionized maritime transport, allowing ships to traverse long distances without relying on wind power.

Steam Turbines

Steam turbines, while also having historical significance, came into prominence later. Charles Parsons, a British engineer, is credited with the invention of the modern steam turbine in the late 19th century. Steam turbines gained prominence in the early 20th century, primarily in the field of power generation. Their efficiency and high power output capabilities made them ideal for producing electricity on a large scale.

Operational Characteristics

Steam Engines

Operating Speed: Steam engines typically operate at lower speeds due to the reciprocating motion of the piston. This limitation in speed can impact their efficiency and suitability for high-speed applications.

Starting and Stopping: Steam engines can be started and stopped relatively quickly, making them suitable for applications that require frequent changes in power output.

Mechanical Stress: The reciprocating motion in steam engines subjects their components to mechanical stress, leading to wear and tear over time. Regular maintenance is necessary to ensure their continued operation.

Steam Turbines

Operating Speed: Steam turbines operate at significantly higher speeds compared to steam engines. The rotary motion of the turbine rotor allows for smoother, continuous operation at high speeds.

Starting and Stopping: Steam turbines are not well-suited for frequent starting and stopping. They require a more stable and continuous operation, making them ideal for applications where a constant power supply is needed.

Mechanical Stress: Steam turbines experience less mechanical stress due to their rotary design, resulting in reduced wear and tear. This leads to lower maintenance requirements.

Efficiency and Energy Conversion

Steam Engines

Steam engines are known for their relatively lower efficiency when it comes to converting thermal energy into mechanical work. This lower efficiency is primarily due to the reciprocating motion, which results in energy losses from friction, heat dissipation, and other mechanical inefficiencies. As a result, steam engines tend to consume more fuel for a given level of power output.

Steam Turbines

Steam turbines are celebrated for their high efficiency in converting thermal energy into mechanical work. The rotary motion and streamlined design of the turbine blades minimize energy losses, making them significantly more efficient than steam engines. This efficiency is a key reason why steam turbines are widely used in power generation, where energy efficiency is of paramount importance.

Specific Application Scenarios

Steam Engines

Where Steam Engines Excel: Steam engines are still found in some niche applications where their characteristics are advantageous. For example:

- Heritage Railways: Steam locomotives are preserved and operated on heritage railways for historical and tourism purposes.

- Antique Machinery: Enthusiasts and museums maintain and demonstrate antique steam-powered machinery.

- Small-Scale Power Generation: In remote or off-grid areas, small steam engines may be used for power generation.

Limitations: Steam engines are less suitable for high-power, high-efficiency, and continuous applications like modern electricity generation and large-scale propulsion.

Steam Turbines

Where Steam Turbines Excel: Steam turbines are the preferred choice in various industries that demand high power output, efficiency, and continuous operation. Key areas of application include:

- Electricity Generation: Steam turbines are the workhorses of power plants, producing electricity for residential and industrial use.

- Marine Propulsion: Large steam turbines power commercial and military vessels, including aircraft carriers and submarines.

- Oil and Gas Industry: Steam turbines drive essential equipment in the extraction, processing, and transportation of oil and gas.

- Industrial Processes: Industries such as chemical, petrochemical, and paper manufacturing rely on steam turbines for diverse processes.

Limitations: While steam turbines are highly efficient and powerful, they are not as versatile as steam engines and may not be well-suited for small-scale or intermittent applications.

Ongoing Innovations

Both steam engines and steam turbines have seen ongoing technological advancements to improve their efficiency, reduce environmental impact, and expand their range of applications. In recent years, innovations in materials, control systems, and design have allowed for greater energy efficiency and reduced emissions in both steam engines and steam turbines.

For example, in the case of steam turbines, advanced blade designs and materials have increased their efficiency and reliability. Turbine technology has also been adapted for use in renewable energy systems, such as geothermal and solar power generation.

On the steam engine front, efforts have been made to increase their efficiency and reduce their environmental footprint. Modern steam engines designed for combined heat and power (CHP) applications have been developed to provide both electricity and useful heat, making them more energy-efficient.

Environmental Considerations

When it comes to environmental impact, steam turbines generally have an advantage over steam engines. Steam turbines are more energy-efficient, which means they consume less fuel and produce fewer emissions per unit of power generated. This makes them a preferred choice for power generation in modern, environmentally conscious societies.

Steam engines, while historically significant, tend to be less efficient and, as a result, can be less environmentally friendly. Their lower efficiency means they consume more fuel to produce the same amount of power, leading to higher emissions. However, in niche applications where historical preservation or aesthetics are valued, environmental considerations may take a back seat to heritage and tradition.

Future Prospects

The future prospects for steam technology continue to evolve. Steam turbines are expected to remain a cornerstone of electricity generation, with ongoing improvements in efficiency and materials contributing to their sustainability. Additionally, advancements in combined heat and power (CHP) systems may see steam engines making a comeback in small-scale, energy-efficient applications.

In the realm of renewable energy, there is ongoing research into using supercritical and ultra-supercritical steam cycles in power plants, which could enhance the efficiency of steam turbines and reduce their environmental impact.

The intersection of steam technology with emerging energy storage and distribution systems, such as hydrogen and fuel cells, also holds promise for the continued evolution of steam-based power generation.

Steam Engine or Steam Turbine : Which One is Right Choose for You?

When it comes to choosing between a steam engine and a steam turbine, your decision should be based on a careful evaluation of your specific needs and requirements. Both technologies have their own advantages and limitations, so let’s break down the key factors to consider when deciding which one is right for you.

Power and Efficiency

Steam Engines:

- Suitable for applications where high power output is not a primary concern.

- Historically significant and valued for heritage and aesthetic purposes.

- Versatile and adaptable to a wide range of applications, particularly in niche or specialty uses.

- May have higher fuel consumption and lower efficiency compared to steam turbines.

Steam Turbines:

- Ideal for high-power applications, such as electricity generation and large ship propulsion.

- Highly efficient in converting thermal energy into mechanical work, resulting in lower fuel consumption.

- Not as versatile as steam engines and best suited for continuous, high-demand operations.

Application and Industry

Steam Engines:

- Found in heritage railways, antique machinery, and smaller, specialty applications.

- Appropriate for applications where tradition, aesthetics, or historical significance are valued.

Steam Turbines:

- Prevalent in power generation, marine propulsion, and heavy industries like oil and gas.

- Suitable for applications that demand a stable, high-power output and energy efficiency.

Operating Speed and Characteristics

Steam Engines:

- Operate at lower speeds due to reciprocating motion.

- Can start and stop quickly, making them suitable for applications with changing power demands.

- Experience more mechanical stress and may require more maintenance due to wear and tear.

Steam Turbines:

- Operate at significantly higher speeds due to rotary motion.

- Not well-suited for frequent starting and stopping; require continuous, stable operation.

- Experience less mechanical stress, resulting in reduced maintenance requirements.

Environmental Considerations

Steam Engines:

- May have higher emissions and fuel consumption due to lower efficiency.

- Valued for their historical significance and aesthetics.

Steam Turbines:

- Generally more environmentally friendly due to their higher efficiency and lower emissions.

- Preferred choice for modern, environmentally conscious societies, particularly in power generation.

Future Prospects

Both steam engines and steam turbines continue to evolve. Steam turbines remain integral to electricity generation, with ongoing advancements in efficiency and sustainability. Steam engines are finding renewed interest in combined heat and power (CHP) systems, making them more energy-efficient in specific applications.

The choice between a steam engine and a steam turbine ultimately depends on your unique needs and priorities. If you value tradition, versatility, or historical significance, a steam engine may be the right choice. However, for high-power, high-efficiency applications with a focus on environmental considerations, steam turbines are the preferred option. Carefully assess your specific requirements to make an informed decision and choose the steam technology that best aligns with your goals.

FAQs

A steam engine operates using reciprocating motion, where steam pushes a piston back and forth, while a steam turbine uses rotary motion, with steam flowing over a series of blades to produce continuous rotation.

Steam turbines are typically more energy-efficient than steam engines due to their rotary design, resulting in lower energy losses and reduced fuel consumption.

Steam engines can be found in heritage railways, antique machinery, and smaller, specialty applications. They are valued for their historical significance and versatility in niche uses.

Steam turbines are commonly used in power generation, marine propulsion, and heavy industries such as oil and gas, where high-power output and efficiency are essential.

Yes, there are environmental differences. Steam engines may have higher emissions and fuel consumption due to lower efficiency, whereas steam turbines are generally more environmentally friendly due to their higher efficiency and lower emissions.

Yes, modern steam engines are being designed for combined heat and power (CHP) systems, making them more energy-efficient and suitable for specific modern applications.

Steam turbines are not well-suited for frequent starting and stopping. They are best for applications that require stable, continuous power output.

Recent innovations include advancements in materials, control systems, and design to enhance efficiency, reduce environmental impact, and expand their range of applications.

Consider factors such as the required power output, efficiency, the need for versatility, environmental impact, and historical significance to make an informed decision.

Read More:

Contents