Polymer Chemistry

Here, we delve into the intricate details of this fascinating field, shedding light on the various terms and other crucial elements that define Polymer Chemistry. Whether you’re a curious student, a passionate researcher, or simply someone interested in expanding their knowledge, this resource will serve as your guide.

-

Polypropylene vs Polystyrene

In the world of plastics, Polystyrene (PS) and Polypropylene (PP) are two prominent players, each with its unique set of characteristics and applications. Understanding the differences between these materials is crucial for selecting the right one for your specific needs. Chemical Composition: Polystyrene is derived from styrene monomers, featuring a benzene ring in its chemical structure, imparting transparency and brittleness. On the other hand, Polypropylene is synthesized from propylene monomers, forming a linear carbon and hydrogen arrangement, resulting in superior heat resistance and toughness. Physical Properties: Polystyrene is known for its transparency, lower density, and limited impact resistance, making it ideal for applications requiring clarity, such as disposable tableware and CD cases. In contrast, Polypropylene offers excellent heat resistance, higher impact resistance, and superior chemical resistance, making it suitable for items like food packaging, automotive parts, and medical devices. Environmental Impact: While neither of these plastics is biodegradable, Polypropylene is often considered more environmentally friendly due to its better recyclability. Cost: Polystyrene is generally more cost-effective, making it a popular choice for disposable and low-cost products, while Polypropylene's cost can vary based on factors like grade and application. Understanding the nuances between Polystyrene and Polypropylene empowers you to make informed decisions, whether you're designing sustainable packaging, engineering durable components, or considering the environmental footprint of your materials.

-

Plastic vs Polycarbonate

In the world of materials, the choice between Polycarbonate and Plastic often plays a pivotal role in the success of a project. While both fall under the category of polymers, these materials differ significantly in terms of composition, properties, and applications. Polycarbonate, known for its exceptional transparency and strength, is derived from repeating carbonates and offers superb impact resistance. It is the material of choice for applications where optical clarity and durability are paramount, such as safety equipment, optical lenses, and aerospace components. Plastic, on the other hand, is a broad term encompassing a diverse range of synthetic polymers, each with its unique chemical composition and characteristics. Plastics vary in transparency, strength, heat resistance, and chemical compatibility, making them suitable for a wide array of applications, including packaging, automotive components, and medical devices. To make an informed choice between Polycarbonate and Plastic, it's essential to consider your project's specific requirements, budget constraints, and environmental goals. Whether you prioritize optical clarity, cost-effectiveness, or sustainability, understanding the differences between these materials empowers you to select the one that aligns perfectly with your needs. Explore the nuances, and navigate the world of materials confidently.

-

Polymer vs Resin

In the realm of materials science, the choice between resin and polymer can significantly impact the success of a project. While these terms are sometimes used interchangeably, they refer to distinct classes of materials with unique characteristics and applications. Resin encompasses a diverse range of materials, including both natural and synthetic compounds. What sets resins apart is their adhesive nature and versatility in coatings and encapsulation. They can be found in everything from woodworking adhesives to the protective coatings on your smartphone screen. Resins are often praised for their chemical resistance and thermal stability, making them valuable in various industrial settings. Polymers, on the other hand, are a more extensive category of materials characterized by the repetition of monomer units. This repeating structure grants polymers their remarkable diversity, from everyday plastics like polyethylene to high-strength composites used in aerospace. Polymers excel in applications where flexibility, lightweight properties, and elasticity are crucial. Intriguingly, some polymers can also function as resins when adhesive or coating properties are required, blurring the lines between these two material classes. Therefore, understanding their differences is paramount in selecting the right material for specific tasks, whether it's crafting artful creations or engineering cutting-edge technologies.

-

Biopolymer vs Polymer

In the ever-evolving realm of materials science, the distinction between polymers and biopolymers is a pivotal one. These substances, although related by name, possess vastly different characteristics, sources, and environmental impacts. Understanding these differences is not only essential for scientists and engineers but also for anyone interested in the sustainable future of our planet. Polymers, often synonymous with synthetic plastics, are derived from petrochemicals through intricate chemical processes. These versatile materials have become ubiquitous in our daily lives, finding applications in countless industries. From the plastic bottles that hold our beverages to the insulation in our homes, polymers are the workhorses of modern manufacturing. However, their dominance comes at a price - their environmental footprint. Many synthetic polymers are non-biodegradable, contributing to long-lasting pollution and resource depletion. Biopolymers, on the other hand, are the natural counterparts. These materials, as the name suggests, originate from living organisms. They include substances like cellulose, found in plant cell walls, and DNA, the genetic code of all life forms. What sets biopolymers apart is their sustainable nature. They are often derived from renewable biological sources and possess the remarkable ability to biodegrade, returning to the Earth without leaving a lasting mark. This eco-friendliness has fueled their adoption in various eco-conscious industries, such as biodegradable packaging and regenerative medicine. As we venture deeper into the realm of polymers and biopolymers, we'll uncover their composition, sources, properties, and applications. We'll also explore the environmental impact, recycling challenges, cost considerations, and regulatory aspects that shape these materials' roles in our world. Join us on this enlightening journey to grasp the "Differences Between Polymer vs Biopolymer" and their significance in the grand tapestry of materials science.

-

Monomer vs Polymer

Polymers and monomers may sound like scientific jargon, but they play pivotal roles in our daily lives. At their core, these terms encapsulate the fundamental building blocks of matter, with unique properties and applications. In our journey to comprehend the distinctions between polymers and monomers, we delve into their molecular structures, chemical properties, and real-world significance. Polymers, those long chains of repeating monomer units, are the unsung heroes of modernity. From the synthetic fibers in our clothes to the plastic containers that store our food, polymers are everywhere. They offer versatility that can be tailored to meet specific needs, making them the backbone of various industries. Monomers, on the other hand, are the precursors, the individual molecules that join together to form polymers. Think of them as the bricks in the construction of molecular architecture. While smaller in size, monomers wield precision and control in chemical synthesis, allowing scientists and engineers to craft materials with exacting specifications. In this guide, we explore the key differences between polymers and monomers, shedding light on their distinct roles in chemistry, industry, and our evolving understanding of materials. From their size and structure to their diverse applications and environmental impacts, we navigate the fascinating world of these chemical entities. Join us as we embark on an enlightening journey to unravel the mysteries of Polymer vs Monomer.

-

Vinyl vs PVC

In the realm of construction and interior design, the choice of materials can make or break a project's success. Two commonly confused materials, PVC (Polyvinyl Chloride) and Vinyl, each bring their unique qualities to the table. To clarify the distinctions and help you make informed decisions for your next endeavor, let's delve into the key differences between PVC vs Vinyl. Material Composition: The primary difference between PVC and Vinyl lies in their material composition. PVC is a synthetic polymer made from vinyl chloride monomers, available in both rigid and flexible forms. Rigid PVC, often referred to as uPVC, is sturdy and used in applications like plumbing and window frames. In contrast, flexible PVC contains plasticizers that make it pliable and ideal for vinyl flooring and medical tubing. On the other hand, Vinyl, specifically PVC-based vinyl, shares the same PVC resin base but is inherently flexible, making it a go-to choice for interior design elements like flooring, upholstery, and wall coverings. Applications: The applications of PVC and Vinyl differ significantly due to their flexibility and durability attributes. PVC is often employed in structural and industrial applications where rigidity and resistance to corrosion are paramount. This includes water pipes, electrical conduits, and window frames. In contrast, Vinyl, with its inherent flexibility, is a preferred choice for interior design projects. It excels in applications such as luxury vinyl flooring (LVP), vinyl upholstery, banners, decals, and more. Vinyl offers a broad spectrum of design options, mimicking the appearance of natural materials like wood and stone, making it a favorite among interior designers and homeowners alike.

-

Plastic vs Polymer

In the vast landscape of materials that shape our world, polymers and plastics stand as two prominent players. While these terms are often used interchangeably, they are not synonymous. Understanding the differences between polymers and plastics is not only fascinating but also essential in today's environmentally conscious era. Composition and Structure: Polymers are a diverse class of materials comprising both natural and synthetic substances. They consist of large molecules formed by repeating structural units, known as monomers. These monomers are chemically bonded together, creating long chains or networks. On the other hand, plastics are a subset of synthetic polymers, specifically chosen for their ability to be molded when exposed to heat or pressure. They are typically derived from petrochemicals through a process called polymerization. Properties: Polymers exhibit a wide range of properties, from flexibility and strength to varying thermal characteristics. Their properties depend on factors like the type of monomers and their arrangement. Plastics, as synthetic polymers, inherit these properties but often have added moldability due to their specific composition. Applications: Polymers find applications in numerous industries, including medical, construction, automotive, and electronics. In contrast, plastics, with their moldable nature, are ubiquitous in packaging, consumer goods, and agriculture, among others. Environmental Impact: One of the most critical distinctions lies in their environmental impact. While some polymers, especially natural ones, can be biodegradable, many synthetic polymers, including traditional plastics, are non-biodegradable and contribute to environmental challenges like plastic pollution.

-

Silicone vs Rubber

Curious about the distinctions between rubber and silicone? These versatile materials play essential roles in various industries. Rubber, derived from natural or synthetic sources, is known for its flexibility and impact resistance. On the other hand, silicone, a synthetic polymer with a silicon-oxygen backbone, excels in extreme heat resistance and versatility across temperature ranges. The heat resistance of silicone makes it suitable for applications involving high temperatures, while rubber offers resilience and flexibility. While rubber is prized for its familiarity and affordability, silicone's exceptional properties come at a higher cost. When choosing between them, consider factors such as your application's needs, budget, and environmental considerations. Whether you're looking for heat resistance, flexibility, or chemical compatibility, understanding these differences will empower you to make an informed decision that aligns with your project's requirements. Explore the world of rubber and silicone, and make the right choice for your unique needs.

-

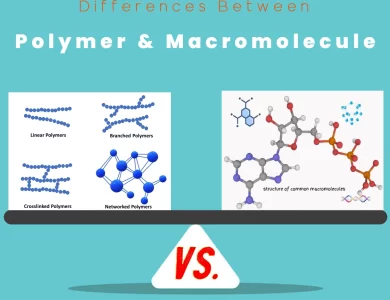

Macromolecule vs Polymer

Dive into the captivating world of polymers and macromolecules, where molecular intricacies shape our understanding of the natural and synthetic realms. These entities, while seemingly related, hold unique characteristics that set them apart in the realm of chemistry. Polymers are akin to the architects of diversity, composed of repeating monomers linked in a chain-like fashion. Their structural variety yields an astonishing range of materials, from flexible rubber to sturdy plastics. On the other hand, macromolecules, the giants of the molecular world, encompass a wide array of structures, including proteins and nucleic acids like DNA and RNA. These molecules, often complex and folded, orchestrate life's processes. At the heart of this comparison lies the distinctive structural nature. Polymer chains exhibit linear or branched arrangements of monomers, while macromolecules boast three-dimensional architectures influenced by intricate bonding forces. The natural and synthetic origins further distinguish them: polymers are found in both living organisms and human-engineered materials, while macromolecules encompass the blueprint of life itself. Properties and applications also set these entities apart. Polymers possess diverse properties tailored for specific uses, from packaging to medical implants. In contrast, macromolecules' intricate folding patterns determine their functions, driving fields like medicine and biotechnology. In the grand narrative of chemistry, the differences between polymers and macromolecules weave a tale of innovation and understanding. Whether you're exploring the quantum mysteries or delving into nanotechnology's frontiers, these entities continue to shape our journey through the intricate world of molecules.

-

UHMW vs HDPE

When it comes to choosing the right polymer for your industrial or commercial applications, understanding the differences between Ultra-High Molecular Weight Polyethylene (UHMW) and High-Density Polyethylene (HDPE) is crucial. These two polymers share a common polyethylene foundation but possess distinct properties that set them apart. UHMW boasts exceptional wear resistance and impact absorption due to its high molecular weight, making it ideal for applications involving constant friction and abrasive interactions. Industries like bulk material handling, conveyor systems, and automotive manufacturing benefit from UHMW's ability to enhance equipment lifespan by reducing wear. On the other hand, HDPE's versatility shines through its balanced mechanical properties, suitable for a wide range of applications. Its adaptability, UV resistance, and cost-effectiveness make it a popular choice for packaging, water management, and outdoor equipment. Additionally, HDPE's ease of machining and broader temperature resistance range contribute to its widespread use. In the realm of temperature resistance, UHMW excels in low-temperature environments, remaining ductile even in freezing conditions, while HDPE showcases better UV resistance for outdoor applications. The choice between UHMW and HDPE hinges on factors like wear resistance, impact resistance, UV exposure, budget, and specific application requirements. By understanding these differences, industries can select the polymer that best aligns with their unique needs, ensuring optimal performance, longevity, and efficiency in their products and processes.

- 1

- 2