| Factor | Purifiers | Clarifiers |

|---|---|---|

| Purpose | Enhancing liquid quality by removing impurities such as solid particles and water. | Separating solids from liquids, with a primary focus on solid-liquid separation. |

| Operating Principle | Relies on centrifugal force to separate different components within a liquid. | Operates on the principle of gravity settling, allowing solids to settle to the bottom. |

| Applications | – Marine and oil sectors<br>- Oil refineries<br>- Power generation<br>- Chemical manufacturing | – Wastewater treatment<br>- Drinking water treatment<br>- Mining<br>- Food and beverage industry |

| Design Complexity | Complex machinery with high-speed rotating components. | Simpler design without high-speed components. |

| Efficiency | High precision in separation but lower throughput capacity. | Efficient solid-liquid separation with higher throughput capacity. |

| Maintenance Requirements | Requires regular maintenance and skilled technicians due to complex components. | Minimal maintenance, basic cleaning, and fewer moving parts. |

| Initial Investment | Higher upfront costs due to complexity. | Lower initial capital investment. |

| Long-term Operating Costs | May have higher long-term operating costs due to maintenance and energy consumption. | Generally lower long-term operating costs with minimal maintenance. |

| Liquid Quality Focus | Focuses on achieving the highest liquid quality. | Primarily concerned with efficient solid-liquid separation. |

| Industry Usage | Marine, oil refining, precision manufacturing, pharmaceuticals. | Wastewater treatment, mining, agriculture, and other industries requiring solid-liquid separation. |

| Environmental Impact | Can help reduce emissions and improve environmental compliance. | Plays a vital role in wastewater treatment and pollution control. |

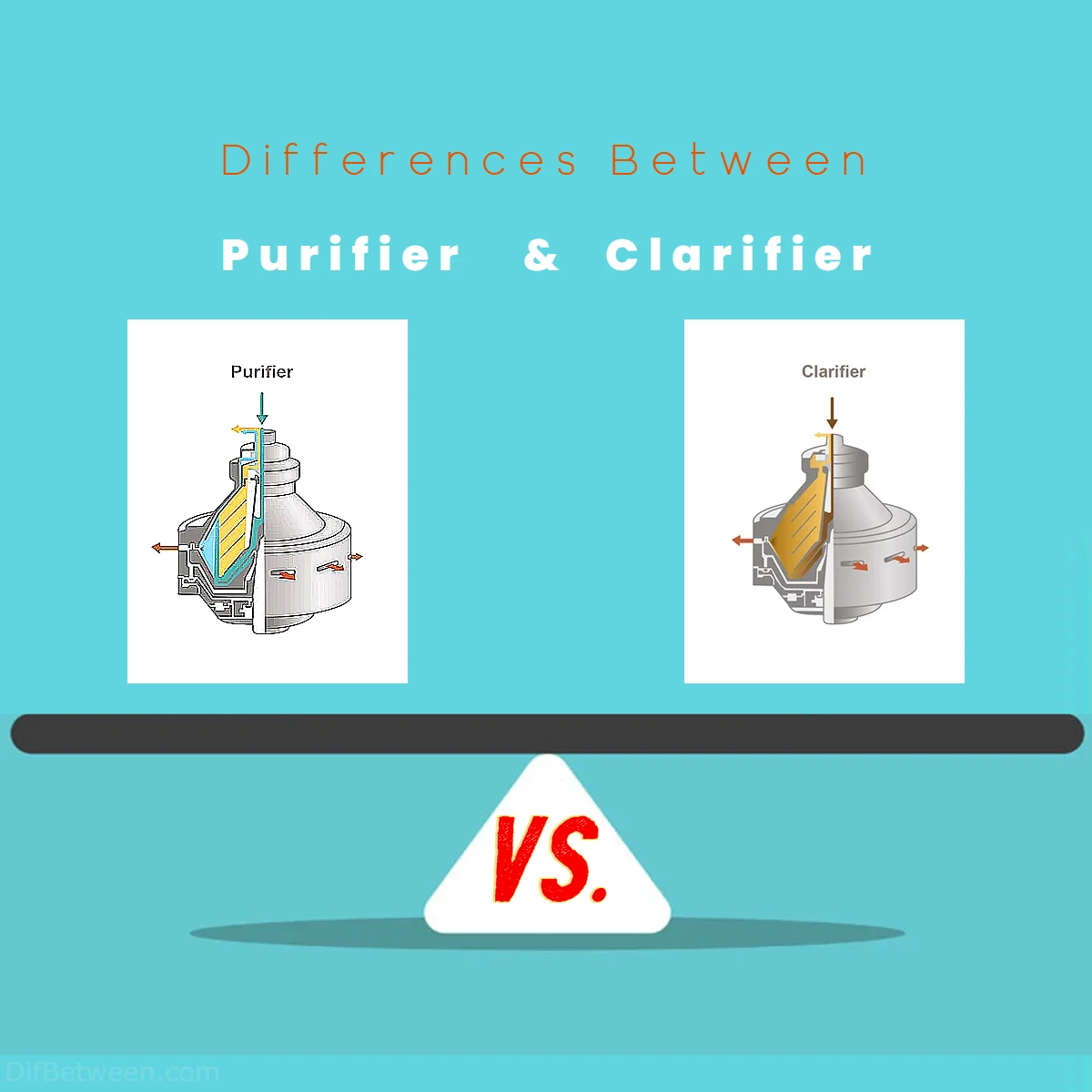

Imagine a world where pristine liquid quality is paramount; enter the Purifier, a precision instrument that wields centrifugal force to meticulously separate unwanted particles from precious fluids. On the flip side, picture a scenario where the main goal is to separate solids from liquids efficiently, without fuss; this is where the Clarifier steps in, relying on the simple yet effective force of gravity.

Differences Between Purifier and Clarifier

The main differences between Purifiers and Clarifiers lie in their fundamental purposes and operating principles. Purifiers are designed for enhancing liquid quality by removing impurities, such as solid particles and water, using centrifugal force. They excel in applications where liquid purity is paramount, like in the marine and oil sectors. On the other hand, Clarifiers primarily focus on solid-liquid separation, operating based on gravity settling. They are ideal for processes such as wastewater treatment and mining, where efficient separation of solids from liquids is the primary goal. In summary, Purifiers prioritize liquid quality enhancement, while Clarifiers specialize in solid-liquid separation, catering to distinct industrial needs.

1. Introduction

Definition of Purifiers

Purifiers are specialized mechanical devices designed to improve the quality of liquids by removing impurities, such as solid particles and water. They are commonly used in industries where maintaining precise liquid quality is essential, such as the marine and oil sectors. Purifiers primarily employ centrifugal force to separate different components of a liquid, ensuring that only the desired components are retained.

Definition of Clarifiers

Clarifiers, on the other hand, are equipment used for the separation of solids from liquids. They are widely utilized in applications where the focus is on removing suspended particles or solids from a liquid medium. Unlike purifiers, clarifiers operate based on the principle of gravity settling, allowing heavier solids to settle to the bottom while clarified liquid is drawn from the top.

2. Purpose and Functionality

Purifiers: Precise Liquid Quality Enhancement

The main purpose of purifiers is to enhance the quality of liquids. In industries like marine and oil, where the purity of fluids is critical for machinery operation and product quality, purifiers are indispensable. They are designed to remove contaminants, such as solid particles, water, and other impurities, from liquids like oil and fuel. This ensures that the liquid meets stringent quality standards, leading to improved equipment performance and reduced maintenance costs.

Purifiers are equipped with sophisticated mechanisms for separating different components within a liquid, making them ideal for applications where achieving a high degree of separation and purity is paramount. They are particularly valuable on ships and in industrial settings where maintaining optimal liquid quality is essential for smooth operations.

Clarifiers: Solid-Liquid Separation

Clarifiers, on the other hand, serve a different purpose. They are primarily used for the separation of solids from liquids. In applications such as wastewater treatment, drinking water purification, and mining, the goal is to remove suspended solids or contaminants from a liquid medium. Clarifiers facilitate this process by allowing heavier particles to settle to the bottom while the clarified liquid is withdrawn from the top.

Unlike purifiers, clarifiers do not aim to enhance the overall quality of the liquid; instead, they focus on removing unwanted solid components. This is crucial in industries where water quality, environmental compliance, and the recovery of valuable solids are key considerations.

3. Operating Principles

Purifiers: Centrifugal Force at Play

Purifiers operate on the principle of centrifugal force. They use a high-speed rotating drum or bowl to generate centrifugal forces that separate different components of the liquid. The heavier particles, such as solid contaminants and water, are forced to the outer edges of the drum due to centrifugal force, while the purified liquid collects in the center and is discharged.

The separated impurities are typically removed through dedicated discharge outlets, ensuring that the purified liquid remains free from unwanted contaminants. This precise separation process is ideal for industries that demand a high level of liquid purity.

Clarifiers: Gravity-Based Settling

Clarifiers rely on the force of gravity to achieve solid-liquid separation. In a clarifier tank, the liquid with suspended solids enters at a controlled flow rate, allowing sufficient residence time for gravity to take effect. As gravity pulls the heavier solid particles downward, they settle at the bottom of the tank, forming a sludge layer.

The clarified liquid, which is now free from most solid contaminants, rises to the top and is carefully skimmed or drawn off for further processing or discharge. Unlike purifiers, clarifiers do not involve high-speed mechanical components, making them simpler and more energy-efficient in operation.

4. Applications

Purifiers: Marine and Industrial Settings

Purifiers find extensive use in marine and industrial settings where the quality of liquids, particularly fuels and lubricants, is critical for the efficient operation of machinery and equipment. Here are some key applications:

- Marine Industry: On ships, purifiers are commonly used to remove water and impurities from heavy fuel oil (HFO) and diesel fuel, ensuring smooth engine performance and preventing damage to engine components.

- Oil Refineries: Purifiers play a crucial role in refining processes, helping maintain the quality of various oils and fuels.

- Power Generation: In power plants, purifiers are used to treat lubricating oils for turbines and generators, minimizing wear and improving equipment reliability.

- Chemical Manufacturing: Purifiers are employed to remove contaminants from various chemical process streams to ensure product quality.

Clarifiers: Water Treatment and Wastewater Management

Clarifiers are widely used in applications where the focus is on solid-liquid separation and the removal of suspended particles. Some key applications include:

- Wastewater Treatment: Clarifiers are integral to wastewater treatment plants, where they help separate solids from wastewater, allowing for the safe discharge of treated water into the environment.

- Drinking Water Treatment: In water treatment facilities, clarifiers are used to remove suspended particles and impurities from raw water sources to produce safe drinking water.

- Mining and Mineral Processing: Clarifiers are employed to separate valuable minerals from ore slurries, facilitating the recovery of valuable resources.

- Food and Beverage Industry: Clarifiers are used to clarify juices, wine, and other liquids in the food and beverage industry, ensuring product quality and clarity.

5. Design and Configuration

Purifiers: Complex Machinery

Purifiers are complex pieces of machinery with multiple components. They typically consist of a high-speed bowl or drum, a series of discs or plates for separation, a drive system to achieve the required rotational speed, and various sensors and controls for monitoring and adjusting the purification process. The design is intricate to achieve the precision required for separating different components effectively.

Due to their complexity, purifiers often require skilled maintenance and regular servicing to ensure they operate at peak efficiency. This complexity also makes them more expensive to purchase and maintain compared to clarifiers.

Clarifiers: Simplicity in Design

In contrast to purifiers, clarifiers are known for their simplicity in design. They consist of a large tank or basin where the settling process occurs, along with inlet and outlet mechanisms for the liquid. There are no high-speed rotating parts or intricate components involved, which contributes to their reliability and ease of operation.

Clarifiers are designed to handle high volumes of liquid and solids with minimal complexity, making them a cost-effective solution for applications where simplicity and efficiency are key factors.

6. Efficiency and Throughput

Purifiers: High Speed, Low Volume

Purifiers are designed for high-speed operation to achieve precise separation of impurities from liquids. This high-speed rotation generates significant centrifugal forces, enabling them to separate even fine particles and water droplets effectively. However, this efficiency comes at the cost of throughput capacity.

Due to their relatively low throughput capacity, purifiers are suitable for applications where maintaining the highest level of liquid purity is crucial, even if it means processing smaller volumes of liquid at a time. They are optimized for quality over quantity.

Clarifiers: Slow Speed, High Volume

Clarifiers operate at significantly slower speeds compared to purifiers. This slow and steady operation allows gravity to perform the separation work, making clarifiers highly efficient in handling large volumes of liquid. They are capable of processing substantial quantities of water or wastewater in a continuous manner.

While clarifiers may not achieve the same level of precision as purifiers in terms of liquid quality, they excel in terms of throughput and are well-suited for applications where separating large volumes of liquid from solids is the primary objective.

7. Maintenance and Cleaning

Purifiers: Regular Maintenance Required

Maintaining purifiers involves regular servicing and cleaning due to their complex machinery and high-speed components. Components such as discs, bowls, and seals need periodic inspection and replacement to ensure proper operation and prevent contamination. Maintenance schedules must be strictly adhered to in order to avoid downtime and maintain liquid quality.

Additionally, purifiers require careful monitoring and adjustment of operating parameters to optimize their performance, adding to the maintenance workload.

Clarifiers: Minimal Maintenance

Clarifiers, with their simpler design and absence of high-speed components, require minimal maintenance. Routine inspections and basic cleaning of the tank and mechanical components are typically sufficient to keep them operational. This simplicity makes clarifiers an attractive option for applications where minimizing maintenance costs and downtime is crucial.

The low maintenance requirements of clarifiers contribute to their cost-effectiveness and reliability in various industries.

8. Cost Considerations

Purifiers: Higher Initial Investment

The initial cost of purchasing and installing a purifier is relatively high compared to clarifiers. The complexity of their design, precision components, and the need for skilled maintenance personnel contribute to their higher upfront expenses. However, the investment in purifiers pays off in industries where liquid quality directly impacts operational efficiency and product quality.

In the long run, the costs associated with purifiers are also influenced by maintenance and operational expenses, including spare parts, energy consumption, and labor.

Clarifiers: Cost-Effective Option

Clarifiers are a cost-effective option for applications that prioritize solid-liquid separation and high throughput. Their simpler design translates into lower initial capital expenditures. Additionally, their minimal maintenance requirements and energy-efficient operation contribute to lower overall operating costs.

While clarifiers may not provide the same level of liquid quality enhancement as purifiers, they offer an economical solution for industries where efficient separation and large-scale processing are the primary objectives.

Purifier or Clarifier: Which One is Right Choose for You?

When it comes to separating solids from liquids or enhancing the quality of fluids, the choice between a purifier and a clarifier is crucial. Each piece of equipment serves a distinct purpose and offers unique advantages. To make the right decision for your specific needs, let’s dive deeper into the key considerations for choosing between a purifier and a clarifier.

Understanding the Basics

Before we explore the decision-making process, let’s quickly recap the fundamental differences between purifiers and clarifiers.

- Purifiers are precision machines designed to improve liquid quality by removing impurities, including solid particles and water. They rely on centrifugal force to achieve high-quality separation and are often used in industries where maintaining precise liquid purity is essential, such as marine and oil sectors.

- Clarifiers, on the other hand, focus on the separation of solids from liquids. They operate on the principle of gravity settling, allowing heavier solid particles to settle to the bottom while clarified liquid is drawn from the top. Clarifiers are commonly used in applications like wastewater treatment and mining, where solid-liquid separation is the primary goal.

Factors to Consider

To determine whether a purifier or a clarifier is the right choice for your application, consider the following factors:

1. Liquid Quality Requirements:

- Purifiers: Choose a purifier if your industry demands the highest level of liquid purity. Purifiers excel at achieving precise separation and removing impurities from fluids, making them suitable for industries like marine, precision manufacturing, and pharmaceuticals.

- Clarifiers: Opt for a clarifier if your primary goal is solid-liquid separation, and liquid quality is not a critical concern. Clarifiers efficiently remove solids from liquids and are commonly used in applications such as wastewater treatment, mining, and agriculture.

2. Throughput Capacity:

- Purifiers: If you have a relatively small volume of liquid to process but require exceptional separation efficiency, purifiers are a good choice. They are ideal for applications with lower liquid throughput.

- Clarifiers: For industries that handle large volumes of liquid on a continuous basis, such as wastewater treatment plants, clarifiers offer high throughput capacity and efficient solid-liquid separation.

3. Maintenance Considerations:

- Purifiers: Keep in mind that purifiers require regular maintenance due to their complex machinery and high-speed components. Ensure you have access to skilled technicians for servicing and upkeep.

- Clarifiers: Clarifiers offer simplicity and minimal maintenance requirements, making them an excellent choice for applications where cost-effective operation is essential.

4. Budget Constraints:

- Purifiers: While they have higher upfront costs, consider the long-term benefits in terms of improved equipment performance and product quality.

- Clarifiers: If budget constraints are a significant factor, clarifiers offer a cost-effective initial investment and ongoing operational savings.

5. Industry-Specific Needs:

- Purifiers: Industries like marine, oil refining, and pharmaceuticals often require purifiers due to stringent quality standards.

- Clarifiers: Industries such as mining, wastewater treatment, and agriculture rely on clarifiers for efficient solid-liquid separation.

6. Environmental Impact:

- Purifiers: In environmentally sensitive industries, purifiers can help reduce emissions and improve compliance with environmental regulations.

- Clarifiers: While not focused on environmental impact, clarifiers play a vital role in wastewater treatment and pollution control.

Making the Informed Decision

Choosing between a purifier and a clarifier is a significant decision that can impact your operations and costs. To make an informed choice, carefully evaluate your specific requirements and consider the factors outlined above. Consult with experts or equipment manufacturers who can provide guidance based on your unique needs.

FAQs

Purifiers are primarily used to enhance liquid quality by removing impurities like solid particles and water, ensuring high-quality fluids. In contrast, Clarifiers focus on solid-liquid separation, efficiently removing solids from liquids

Purifiers use centrifugal force to separate components within a liquid, pushing heavier particles outward, while clarified liquid collects in the center. Clarifiers, on the other hand, rely on gravity settling, allowing heavier solids to settle to the bottom as clarified liquid rises to the top.

Purifiers find application in industries such as marine, oil refining, power generation, and precision manufacturing, where maintaining precise liquid quality is crucial.

Clarifiers are commonly used in applications like wastewater treatment, drinking water purification, mining, and the food and beverage industry, where efficient solid-liquid separation is essential.

Purifiers have complex machinery with high-speed rotating components, while Clarifiers have a simpler design with fewer moving parts and no high-speed components.

Clarifiers tend to be more cost-effective in terms of long-term operating costs due to their minimal maintenance requirements and lower initial capital investment compared to Purifiers.

Purifiers can help reduce emissions and improve environmental compliance in industries like marine and oil refining, while Clarifiers play a vital role in wastewater treatment and pollution control.

Read More:

Contents