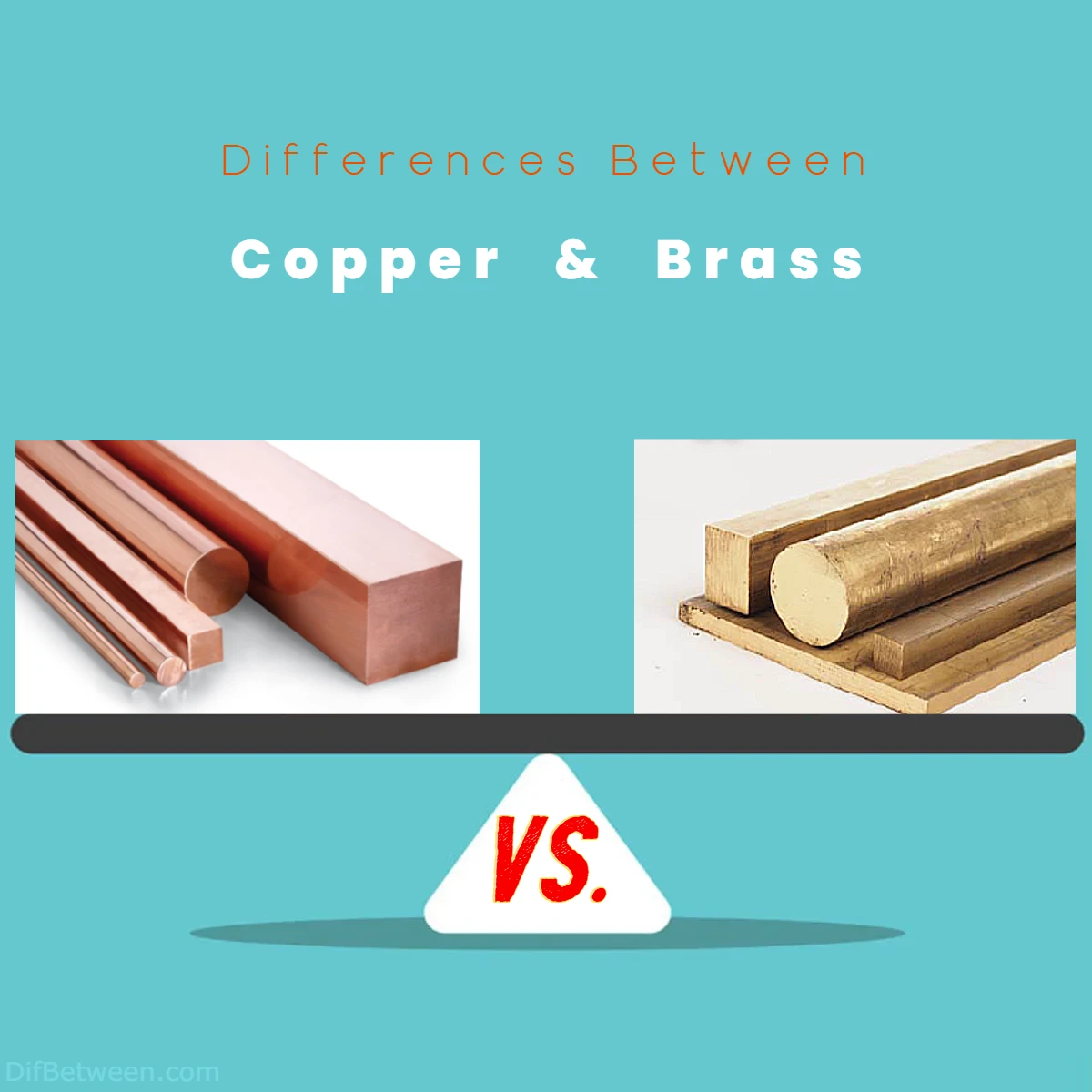

| Attribute | Copper | Brass |

|---|---|---|

| Chemical Symbol | Cu (Copper) | Cu + Zn (Copper + Zinc) |

| Color | Reddish-brown | Varied (depending on copper-zinc ratio) |

| Conductivity | Excellent electrical and thermal | Limited electrical conductivity |

| Malleability | Highly malleable | Malleable, influenced by zinc content |

| Strength | Relatively soft | Enhanced strength due to zinc content |

| Corrosion Resistance | Develops protective patina | Resistant to tarnishing, minimal oxidation |

| Appearance Over Time | Develops patina with exposure | Retains lustrous appearance |

| Applications | Electrical wiring, plumbing, art | Musical instruments, decorative items, plumbing |

| Recyclability | Highly recyclable | Recyclable, composition considerations |

| Environmental Impact | Sustainable and energy-efficient | Challenges due to composition, some brasses may contain lead |

| Cost | May be higher due to superior properties | Generally more affordable than precious metals |

| Longevity | Develops protective patina | Requires regular polishing and maintenance |

| Aesthetics | Natural patina or polished elegance | Lustrous appearance, gold-like shine |

Imagine the glint of sunlight on an ornate doorknob or the hum of electricity coursing through wires – these are just glimpses of the vast domains that copper and brass occupy. With an unmatched ability to conduct both electricity and heat, copper stands tall in the realm of electrical engineering, from power grids to communication networks. Yet, its allure doesn’t stop there – copper’s propensity to develop a distinguished patina over time turns architectural marvels into time-worn treasures, a testament to its enduring beauty.

Differences Between Copper and Brass

The main differences between copper and brass lie in their composition and properties. Copper, symbolized as Cu, is an elemental metal known for its exceptional electrical and thermal conductivity. In contrast, brass is an alloy of copper and zinc, offering a unique blend of malleability and strength. While copper develops a protective patina over time and finds application in electrical wiring and plumbing due to its corrosion resistance, brass boasts a lustrous appearance that appeals to decorative and architectural uses. These distinctions make copper ideal for conductivity-driven industries, while brass excels in applications where aesthetics and durability intersect.

Composition and Origins

Copper: A Foundational Element

Copper, an elemental metal with the chemical symbol Cu and atomic number 29, has been an integral part of human civilization for thousands of years. It’s one of those naturally occurring wonders that played a pivotal role in the transition from the Stone Age to the Bronze Age. Malleable and conductive, copper’s reddish-brown hue has adorned architectural marvels, artwork, and everyday objects.

In its pure form, copper is soft and pliable, making it suitable for various applications. However, its pure state is often alloyed with other metals to enhance its properties for specific uses. Notably, copper’s excellent electrical conductivity and corrosion resistance have secured its place in electrical wiring, telecommunications, and various industrial sectors.

Brass: A Fusion of Artistry and Utility

Brass, on the other hand, is a stunning alloy composed primarily of copper and zinc. This alloying process is like a dance between the two metals, resulting in an alloy that inherits the durability and versatility of copper while acquiring the attractive gold-like appearance of brass. Depending on the proportions of copper and zinc, brass can span a spectrum of colors, from reddish to yellow to even silvery.

The composition of brass can vary widely, leading to an array of brass types, each optimized for specific applications. This diversity in composition lends brass its versatility, allowing it to be transformed into musical instruments, decorative pieces, plumbing fittings, and more.

Physical Attributes

Copper: Strength in Malleability

Copper, in its pure form, is a relatively soft metal that possesses exceptional malleability. This means it can be easily shaped, formed, and stretched without fracturing. This attribute has made copper a favorite among artisans and craftsmen for intricate metalwork and decorative purposes. Its conductivity also extends to heat, making it a sought-after material for cookware.

However, the softness of pure copper can be a drawback in applications where hardness and strength are essential. This is where copper alloys come into play, providing a way to retain copper’s advantageous properties while mitigating its inherent weaknesses.

Brass: The Balance of Strength and Aesthetics

Brass inherits some of copper’s malleability but gains additional strength from the presence of zinc. This amalgamation of characteristics makes brass a formidable choice for applications that demand both structural integrity and visual appeal. From the intricate details of musical instruments to the sturdiness of doorknobs, brass strikes a balance that few other materials can achieve.

The exact properties of brass, such as hardness, tensile strength, and corrosion resistance, depend on the specific composition of the alloy. This variability allows manufacturers to tailor brass to suit a wide range of industries, from automotive to architecture.

Corrosion and Durability

Copper: Weathering with Character

Copper possesses a distinct quality that sets it apart from many other metals: its ability to develop a patina over time. When exposed to the elements, copper interacts with moisture, oxygen, and other environmental factors, resulting in a gradual color change. This transformation, known as patination, gives copper a distinguished appearance that’s often associated with aged architecture and statues.

While the patina might alter copper’s aesthetic, it actually serves as a protective layer, shielding the metal from further corrosion. This characteristic makes copper an ideal choice for roofing, outdoor sculptures, and architectural embellishments.

Brass: Lustrous Resilience

Brass, being an alloy of copper, also exhibits corrosion resistance, albeit in a different manner. It lacks the patina-forming tendency of copper, instead retaining its lustrous surface with minimal oxidation. This resistance to tarnishing makes brass a favored material for decorative items, jewelry, and musical instruments, where aesthetics play a significant role.

However, it’s worth noting that the specific composition of brass can influence its susceptibility to corrosion. High-zinc brasses, for instance, might be more prone to dezincification—a type of corrosion that affects the zinc-rich phase of the alloy. This highlights the importance of selecting the right brass type for the intended application.

Applications and Industries

Copper: Conducting the Current of Innovation

Copper’s unparalleled electrical conductivity makes it an essential element in the world of electrical engineering. From power generation to transmission and distribution, copper wiring forms the nervous system of our electrified world. Its thermal conductivity also finds applications in cooking utensils and heat exchangers.

But copper’s utility goes beyond the realm of electricity. It’s a crucial component in plumbing systems due to its corrosion resistance and biostatic properties. Furthermore, copper’s antimicrobial characteristics have led to its incorporation in healthcare settings, where it helps reduce the transmission of pathogens.

Brass: Where Form Meets Function

Brass’s winning combination of strength, corrosion resistance, and visual appeal positions it as a versatile player in various industries. Its use in musical instruments, such as trumpets and saxophones, showcases its acoustic properties and the ease with which it can be shaped into intricate designs. Additionally, its malleability has made it a staple in crafting detailed hardware and decorative elements.

Plumbing benefits from brass’s resistance to corrosion, particularly in environments with exposure to water. Its gold-like appearance lends an air of elegance to fittings and fixtures in both residential and commercial spaces. And let’s not forget its presence in nautical applications, where its resistance to saltwater corrosion is of paramount importance.

Environmental Considerations

Copper: Sustainability and Recycling

One aspect often overlooked in the comparison of metals is their environmental impact. Copper stands out in this regard due to its recyclability and sustainability. Recycling copper is not only energy-efficient but also helps conserve natural resources. The demand for copper is met to a significant extent through recycling, reducing the need for extensive mining.

Copper’s long life cycle also contributes to its eco-friendliness. In applications like roofing, where copper’s durability shines, the need for replacements is minimized. Moreover, its biocidal properties make it valuable for water treatment systems, further enhancing its environmental benefits.

Brass: Recyclability and Composition Challenges

Recycling brass presents some unique challenges due to its composition. Since brass can consist of varying proportions of copper and zinc, recycling requires careful separation and processing. However, advancements in metallurgical technologies are continually improving the efficiency of brass recycling.

It’s important to note that some brasses might contain traces of lead, which can complicate their recycling and raise concerns about environmental safety. Therefore, responsible manufacturing and recycling practices are crucial to ensure brass’s sustainability.

Cost Considerations

Copper: An Investment in Quality

Copper’s intrinsic value is often reflected in its price. While it might be pricier than certain alternative materials, its exceptional properties and longevity make it a worthwhile investment, especially in applications where conductivity, corrosion resistance, and reliability are paramount.

Copper’s cost-effectiveness becomes evident in scenarios where its unique characteristics lead to reduced maintenance, enhanced energy efficiency, and increased product lifespan. The initial expense can often be outweighed by long-term benefits.

Brass: Balancing Aesthetics and Economy

Brass offers an interesting balance between aesthetics and cost. Its resemblance to gold, coupled with its durability, makes it an attractive alternative to more expensive materials in applications where visual appeal matters. While not as cost-prohibitive as precious metals, brass’s versatility can help achieve a high-end look without breaking the bank.

In architectural elements, for instance, brass fittings and accents can impart a sense of luxury without the steep price tag. This makes brass an excellent choice for projects that demand a refined appearance while adhering to budget constraints.

Maintenance and Care

Copper: Aging with Grace

The development of a patina on copper surfaces is a natural process that adds character over time. However, some may prefer the original reddish-brown appearance. For such individuals, regular maintenance is required to prevent patination. Various cleaning solutions and methods can help restore copper to its original shine, though the patina’s protective benefits will be lost.

Brass: Polishing for Perfection

Brass’s allure lies in its lustrous shine, but this sheen can be susceptible to tarnishing over time, especially when exposed to air and moisture. Regular polishing and maintenance are necessary to retain brass’s appealing appearance. Commercial brass cleaners and DIY solutions can help remove tarnish and restore the metal’s brilliance.

In the case of decorative items, musical instruments, and hardware, regular maintenance becomes an essential aspect of preserving the visual and functional aspects of brass.

Copper or Brass: Which One is Right Choose for You?

When faced with the decision of whether to opt for copper or brass, it’s essential to consider your specific needs, preferences, and the intended application. Both metals bring a distinct set of qualities to the table, making the choice a matter of aligning these attributes with your requirements. Let’s delve deeper into the considerations that can guide your decision-making process.

Consider the Application

Copper: Electrical Excellence and Beyond

If your project involves electrical conductivity, copper is an unrivaled choice. Its exceptional ability to conduct both electricity and heat makes it indispensable in electrical wiring, power generation, and transmission applications. Copper’s antimicrobial properties also make it a prime candidate for healthcare settings, plumbing, and water treatment systems.

Furthermore, if your application will be exposed to the elements, consider copper’s patination process. The development of a protective patina over time can lend a timeless, weathered appearance to architectural elements, sculptures, and outdoor installations.

Brass: Aesthetic Appeal and Strength

For applications where aesthetics and strength take center stage, brass shines. Its alluring golden appearance, combined with its durability, makes it a prime candidate for decorative items, architectural accents, and musical instruments. The malleability of brass allows for intricate designs and detailed craftsmanship that can elevate the visual appeal of your project.

If your project involves plumbing or fixtures that come into contact with water, brass’s corrosion resistance makes it a valuable choice. Its ability to retain its shine with minimal oxidation can contribute to the longevity of your design.

Balance of Strength and Malleability

Copper: Softness with a Purpose

Copper’s softness and malleability are advantageous in applications that require shaping and forming. However, if your project demands high mechanical strength, you might need to consider copper alloys that provide enhanced durability while preserving its other beneficial properties.

Brass: A Versatile Compromise

Brass strikes a balance between copper’s malleability and the need for mechanical strength. The addition of zinc to copper enhances its hardness and makes it suitable for a wide range of applications, from intricate artistic endeavors to functional hardware.

Longevity and Maintenance

Copper: Aging Gracefully

If you appreciate the evolution of materials over time, copper’s patina-forming tendency could be a plus. This natural transformation not only adds character but also serves as a protective layer against corrosion. Keep in mind that maintenance might be necessary if you prefer the original appearance of copper.

Brass: Polished Elegance

Brass’s lustrous appearance offers an enduring shine, but it requires regular maintenance to prevent tarnishing. Polishing can restore its brilliance, making it an ideal choice for projects where visual appeal remains a priority.

Budget and Sustainability

Copper: Investment for the Future

Copper’s initial cost might be higher, but its longevity and exceptional properties can lead to long-term savings. Its recyclability and sustainability, coupled with reduced maintenance needs, can make it a worthwhile investment.

Brass: Affordability and Elegance

Brass offers a more cost-effective solution without compromising on aesthetics. Its visual appeal makes it an attractive alternative to more expensive materials, allowing you to achieve a luxurious look without an extravagant budget.

In Summary

In the decision between copper and brass, there’s no one-size-fits-all answer. The right choice depends on the nature of your project, your priorities, and the attributes you value most. Consider the specific application, the desired balance of strength and malleability, the longevity and maintenance aspects, as well as your budget and sustainability goals.

Both copper and brass have left an indelible mark on architecture, industry, art, and everyday life. Their individual stories and attributes enrich the world around us, showcasing the power of materials to shape our experiences. So, whether you’re crafting a timeless masterpiece or engineering a modern marvel, the choice between copper and brass is a journey of exploration and discovery, leading you to the perfect metal match for your vision.

FAQs

The primary distinction between copper and brass lies in their composition. Copper is a pure elemental metal (Cu), while brass is an alloy composed of copper and zinc. This composition gives brass its unique blend of characteristics, including enhanced strength and a wide range of colors.

Copper is renowned for its exceptional electrical and thermal conductivity, making it one of the best conductors of electricity. Brass, on the other hand, has limited electrical conductivity due to its alloy composition, with zinc acting as a conductivity-reducing component.

Copper typically exhibits a reddish-brown hue and develops a distinctive patina over time due to its interaction with the environment. In contrast, brass can display a variety of colors, ranging from yellow to reddish-brown to even silvery tones, depending on the copper-zinc ratio in the alloy.

Copper is highly malleable and ductile, making it easy to shape and form into intricate designs. Brass retains some malleability due to the copper content, but its hardness increases with the addition of zinc, providing a balance between malleability and strength.

Yes, there are differences. Copper develops a protective patina over time, which acts as a shield against corrosion. Brass, while resistant to tarnishing, lacks the natural patina-forming tendency of copper. However, specific types of brass may be more susceptible to certain forms of corrosion, depending on their composition.

Copper’s excellent electrical conductivity makes it indispensable in electrical wiring, telecommunications, and power distribution industries. It’s also prevalent in plumbing systems and architectural elements. Brass’s strength and aesthetic appeal find applications in decorative items, musical instruments, plumbing fittings, and architectural accents.

Copper, often considered a premium metal due to its properties, can be relatively higher in cost. Brass, while not as expensive as precious metals, provides an affordable yet visually appealing alternative for applications where aesthetics matter.

Yes, both copper and brass are recyclable. Copper’s high recyclability contributes to its sustainability and conservation of resources. Recycling brass requires separation and processing due to its alloy composition, but advancements in recycling technologies have made brass recycling more efficient.

Copper’s recyclability and sustainable nature contribute to its favorable environmental profile. Brass, due to potential variations in composition and the presence of trace elements like lead in some types, requires responsible manufacturing and recycling practices to ensure its environmental impact is managed effectively.

Brass is often favored for applications that require a balance between aesthetics and strength. Its unique combination of durability and visual appeal makes it a popular choice for decorative elements, architectural accents, and musical instruments.

Read More: