| Aspect | Zinc | Zinc Oxide |

|---|---|---|

| Chemical Formula | Zn | ZnO |

| Composition | Elemental metal (Zn) | Compound of zinc and oxygen (ZnO) |

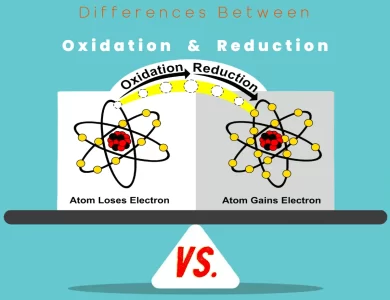

| Oxidation State | Typically +2 | Zinc: +2, Oxygen: -2 |

| Structure | Transition metal with crystalline structure | Crystalline structure, can vary with temp. |

| Physical Properties | Malleable, ductile, lower electrical conductivity | White powder, higher melting point |

| Applications | Galvanization, brass alloy, anodes | Sunscreen, cosmetics, pharmaceuticals |

| Safety | Essential micronutrient, toxicity in excess | Generally recognized as safe, GRAS |

| pH Behavior | Zinc reacts with acids to release hydrogen gas | Zinc oxide is amphoteric, reacts with acids and bases |

| Environmental Impact | Improper disposal can harm ecosystems | Concerns about nanoparticle dispersion |

| Manufacturing | Extraction from ores, roasting, reduction | Indirect and direct processes |

| Optical/Electronic | Used in alloys, semiconducting materials | Wide-bandgap semiconductor, LEDs, sensors |

| Nanotechnology | Limited nanoparticle use due to toxicity | Applications in catalysis, drug delivery |

| Solubility | Not soluble in water | Slightly soluble, forms complexes |

| Biological Role | Essential trace element | Mild antiseptic, UV protection |

| Crystal Structure | Hexagonal Close-Packed (HCP) | Wurtzite crystal structure |

Comprehensive exploration of the key differences between zinc and zinc oxide. Both of these substances hold significant importance in various industries and applications. In this engaging narrative, we will delve into their unique aspects, offering you a clear understanding of what sets them apart.

Differences Between Zinc and Zinc Oxide

The main differences between zinc and zinc oxide lie in their composition and properties. Zinc is a metallic element known for its malleability and ductility, commonly used in galvanization and alloy production. On the other hand, zinc oxide is a compound of zinc and oxygen, appearing as a white powder with a higher melting point. Unlike zinc, zinc oxide lacks electrical conductivity and is often utilized in sunscreens, cosmetics, and pharmaceuticals due to its UV-blocking and antiseptic properties. Understanding these distinctions is essential to grasp their unique roles in various industries and applications.

1. Composition and Structure

Zinc: Let’s start by uncovering the elemental nature of zinc. This bluish-white metal boasts a shiny surface when freshly exposed. It is categorized as a transition metal on the periodic table, with the symbol “Zn” and atomic number 30. Zinc is commonly extracted from its ore, sphalerite, through a process that involves roasting and then reduction with carbon. The resulting metal finds its way into numerous applications due to its exceptional anti-corrosion properties.

Zinc Oxide: Now, shifting our focus to zinc oxide, a compound of zinc and oxygen. Its chemical formula, ZnO, signifies its composition – one zinc atom bonded with one oxygen atom. Structurally, zinc oxide exists in a crystalline form, and its lattice structure can vary based on temperature and production methods. This compound occurs naturally as the mineral zincite but can also be synthesized for various purposes, including its utilization in industries like cosmetics, pharmaceuticals, and rubber manufacturing.

2. Physical Properties

Zinc: As we assess the physical properties of zinc, we encounter a malleable and ductile metal. It holds a melting point of approximately 419.5°C (787.1°F) and a boiling point of around 907°C (1665°F). What’s intriguing is that zinc displays a relatively low electrical conductivity compared to other metals, making it useful in galvanizing processes and as an anode material in batteries. The metal’s density, 7.13 grams per cubic centimeter, contributes to its lightweight and versatile nature.

Zinc Oxide: When transitioning to zinc oxide’s physical properties, we find a stark contrast. This compound is inorganic and typically appears as a white powder. Remarkably, zinc oxide remains stable at high temperatures, showcasing its resilience in various applications. It holds a melting point of approximately 1975°C (3587°F), significantly higher than that of pure zinc. Moreover, its lack of electrical conductivity diverges from zinc’s behavior, making it suitable for applications requiring insulating properties.

3. Applications in Industries

Zinc: The applications of zinc span a wide array of industries, rendering it a versatile and indispensable material. One of its most prominent roles is in the realm of corrosion prevention, where it is used as a protective coating on iron and steel, a process commonly referred to as galvanization. This extends the lifespan of structures and objects exposed to harsh environmental conditions. Zinc’s presence in the brass alloy enhances its workability, making it a preferred choice in musical instruments, plumbing fittings, and decorative items.

Zinc Oxide: On the other hand, zinc oxide’s applications take a diverse route. Due to its remarkable ability to absorb ultraviolet (UV) light, it is a coveted ingredient in sunscreens and skincare products. The pharmaceutical industry leverages its mild antiseptic properties in ointments and creams. Moreover, its role as a rubber vulcanization agent contributes to the production of durable rubber goods. This compound’s applications extend to the realm of electronics, where it serves as a component in varistors, devices that protect against voltage surges.

4. Toxicity and Safety Considerations

Zinc: The elemental form of zinc is an essential micronutrient for both plants and animals. Human bodies require a certain amount of zinc for various physiological processes. However, excessive intake can lead to adverse effects, such as nausea and vomiting. Occupational exposure to zinc dust or fumes should also be monitored to prevent respiratory issues known as metal fume fever. Hence, while zinc is vital, moderation is key.

Zinc Oxide: The safety considerations regarding zinc oxide are notably different. This compound is generally recognized as safe (GRAS) by the U.S. Food and Drug Administration (FDA) when used in specific applications, like food additives and over-the-counter medications. It is important to note that inhalation of fine zinc oxide particles should be avoided, as it can lead to respiratory concerns. In the realm of cosmetics, nanoparticle-sized zinc oxide has raised debates about potential skin absorption and long-term effects, although research in this area is ongoing.

5. Environmental Impact

Zinc: Zinc’s impact on the environment largely depends on the context. While it is not classified as a hazardous waste, improper disposal or release of zinc-containing substances can harm aquatic life and soil quality. Zinc pollution can also result from industrial processes, affecting nearby ecosystems. As a result, regulatory measures and responsible disposal practices are crucial to mitigate its environmental impact.

Zinc Oxide: The environmental considerations for zinc oxide are closely related to its applications. In sunscreen formulations, the dispersion of nanoparticle-sized zinc oxide has raised concerns about its potential impact on aquatic organisms when washed off into water bodies. However, the sun-protective benefits of zinc oxide in reducing the risk of skin cancer must also be weighed against these potential environmental effects.

6. Manufacturing Processes

Zinc: The production of elemental zinc involves a series of steps. It primarily starts with the extraction of zinc ores, which are primarily sulfide minerals like sphalerite. The ore is first roasted to convert the zinc sulfide into zinc oxide. Then, the zinc oxide is reduced using carbon or other reducing agents to obtain the elemental zinc. This process can involve high temperatures and energy consumption.

Zinc Oxide: The manufacturing of zinc oxide can be achieved through various methods. The most common approaches include the indirect or French process and the direct or American process. In the indirect process, zinc metal is vaporized, oxidized, and then condensed into zinc oxide particles. The direct process involves the oxidation of zinc vapors generated by the combustion of zinc metal. Both methods result in the production of high-purity zinc oxide for different applications.

7. Optical and Electronic Properties

Zinc: In the realm of optics and electronics, zinc finds its role primarily as a component of various alloys rather than a direct material of interest. For example, zinc is a key element in producing semiconducting materials like zinc selenide and zinc sulfide. These materials exhibit specific optical and electronic properties that make them useful in various applications such as infrared optics and photovoltaic devices.

Zinc Oxide: Zinc oxide’s optical and electronic properties are quite distinctive and have led to its applications in emerging technologies. It is a wide-bandgap semiconductor with intrinsic n-type conductivity. This means it can conduct electrons effectively. These properties make it suitable for applications in transparent conductive films, light-emitting diodes (LEDs), and even thin-film transistors. The combination of its transparency and electrical conductivity makes zinc oxide a valuable material for the development of next-generation electronic devices.

8. Nanoparticles and Nanotechnology

Zinc: In the world of nanotechnology, zinc has found its way into various forms, including nanoparticles. These nanoparticles can be engineered for specific applications such as catalysis and antibacterial agents. However, the use of zinc nanoparticles is more limited compared to other nanoparticles due to certain toxicity concerns.

Zinc Oxide: Zinc oxide nanoparticles, on the other hand, have gained significant attention in the field of nanotechnology. These nanoparticles exhibit unique properties at the nanoscale, including enhanced reactivity and a larger surface area compared to bulk zinc oxide. They find applications in areas such as photocatalysis, antimicrobial coatings, and even targeted drug delivery systems. The tunable properties of zinc oxide nanoparticles make them a versatile tool for various technological advancements.

9. Solubility and Dissolution Behavior

Zinc: Elemental zinc is not soluble in water, which is a property that contributes to its use as a coating to protect iron and steel from corrosion. This non-solubility is essential in preventing the zinc layer from being easily dissolved by environmental factors.

Zinc Oxide: Zinc oxide, as a compound, exhibits different solubility characteristics. It is slightly soluble in water but can form complexes with various organic and inorganic compounds that influence its solubility behavior. This solubility property can have implications for its environmental impact, especially when considering the release of zinc ions from products like sunscreens into aquatic environments.

10. Role in Biological Systems

Zinc: In the biological realm, zinc plays a vital role as an essential trace element. It is crucial for numerous enzymatic reactions, DNA synthesis, immune function, and wound healing. Deficiencies in zinc can lead to various health issues, making it an important dietary element for humans and animals.

Zinc Oxide: Zinc oxide’s role in biological systems is not as direct as elemental zinc. However, due to its mild antiseptic and UV-blocking properties, it has found applications in healthcare and cosmetics. It is used in products like diaper creams, lotions, and ointments to promote healing and protect the skin from UV radiation.

As we wrap up this journey through the facets of zinc and zinc oxide, we’ve uncovered their distinct features that set them apart while maintaining a connection through their shared elemental origin. From their composition to their impact on industries and the environment, these materials continue to shape our world in unique and innovative ways. Whether as a protective coating, an electronic component, or a vital micronutrient, the diverse roles of zinc and zinc oxide showcase the marvels of materials science and the complexity of our natural world.

FAQs

The primary difference lies in their composition. Zinc is a metallic element, while zinc oxide is a compound of zinc and oxygen.

Zinc is malleable and ductile with lower electrical conductivity, while zinc oxide appears as a white powder with a higher melting point and lacks electrical conductivity.

Zinc is commonly used for galvanization, alloy production, and as an essential micronutrient. Zinc oxide finds its place in sunscreens, cosmetics, pharmaceuticals, and electronic devices.

While zinc is an essential nutrient, excessive intake can be harmful. Zinc oxide is generally recognized as safe (GRAS), but precautions should be taken with inhalation and nanoparticle use.

Zinc requires responsible disposal to prevent harm to ecosystems. Zinc oxide’s environmental impact is linked to nanoparticle dispersion and its presence in products like sunscreens.

Zinc serves as a vital micronutrient for enzymatic reactions and immune function. Zinc oxide, with mild antiseptic properties, is used in healthcare and cosmetics.

Zinc is extracted from ores and reduced, while zinc oxide can be produced through indirect or direct methods, resulting in high-purity zinc oxide particles.

Zinc nanoparticles are limited due to toxicity concerns, while zinc oxide nanoparticles are widely used for catalysis, drug delivery, and other technological advancements.

Zinc is used in alloys and semiconducting materials. Zinc oxide’s wide-bandgap semiconductor properties make it valuable for transparent conductive films, LEDs, and sensors.

Elemental zinc is not soluble in water. Zinc oxide is slightly soluble and can form complexes with other compounds, influencing its solubility behavior.

Read More:

Contents

- Differences Between Zinc and Zinc Oxide

- 1. Composition and Structure

- 2. Physical Properties

- 3. Applications in Industries

- 4. Toxicity and Safety Considerations

- 5. Environmental Impact

- 6. Manufacturing Processes

- 7. Optical and Electronic Properties

- 8. Nanoparticles and Nanotechnology

- 9. Solubility and Dissolution Behavior

- 10. Role in Biological Systems

- FAQs