| Aspect | Dilution | Concentration |

|---|---|---|

| Definition | Reducing the concentration of a solute by adding more solvent. | Increasing the amount of solute in a solution. |

| Purpose | Decreasing solution strength, often for safety, precision, or specific requirements. | Increasing solution strength for reactions, preservation, or potency. |

| Applications | – Scientific experiments – Medicine preparation – Food and beverages – Analytical chemistry – Environmental testing | – Chemical synthesis – Food preservation – Industrial processes – Pharmaceutical industry – Flavor extraction |

| Methods | – Volumetric dilution – Serial dilution – Dilution by weight – Dilution by molarity – Dilution by serial transfer | – Evaporation – Crystallization – Reverse osmosis – Centrifugation – Freeze concentration |

| Calculation Formula | C1V1 = C2V2 (for dilution factor) | Concentration (C) = (Amount of Solute) / (Volume of Solvent) |

| Examples in Real Life | – Medication preparation – Preparing beverages – Environmental testing | – Chemical reactions – Food preservation – Industrial processes |

| Safety Considerations | Often used for safety, especially with hazardous substances. | Concentrated solutions may require careful handling due to potency. |

| Equipment | May use common laboratory equipment like pipettes and graduated cylinders. | May require specialized equipment like rotary evaporators or centrifuges. |

| Precision | Used when precise control over concentration is needed. | Often used in processes where fine-tuning concentration is critical. |

| Environmental Impact | Dilution can lead to less waste generation compared to concentration. | Concentration processes may have a higher energy and resource cost. |

Have you ever found yourself in a situation where you needed to adjust the strength of a solution? Perhaps you were in the kitchen, fine-tuning the flavors of your favorite dish, or maybe you encountered the concept while conducting experiments in a laboratory. The processes of dilution and concentration are the unsung heroes behind these everyday scenarios.

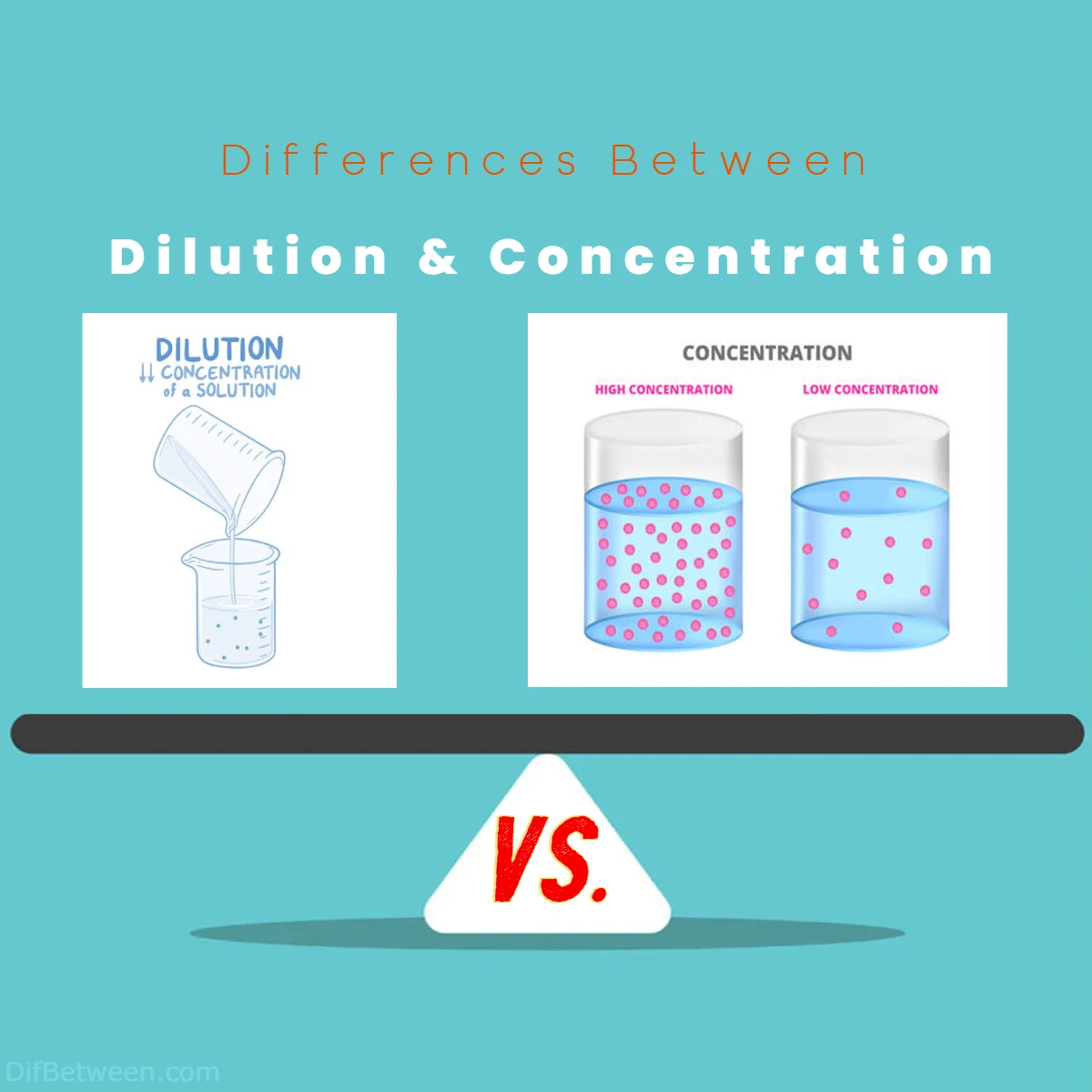

Differences Between Dilution and Concentration

The main differences between dilution and concentration lie in their core objectives and methods. Dilution involves reducing the concentration of a solution by adding more solvent, often used for safety, precision, or customization purposes. In contrast, concentration focuses on increasing the amount of solute in a solution, employed in various applications like chemical reactions, preservation, and enhancing potency. These two processes, while seemingly opposite, are essential tools across scientific, industrial, and everyday contexts, each tailored to achieve specific outcomes.

1. Defining

Dilution: The process of reducing the concentration of a solute.

Dilution, in simple terms, is the act of making a solution less concentrated by adding more solvent to it. This results in a decrease in the amount of solute per unit volume while maintaining the total amount of solute constant. Dilution is commonly represented using the formula:

C1V1 = C2V2

Where:

- C1 is the initial concentration of the solution.

- V1 is the initial volume of the solution.

- C2 is the final concentration after dilution.

- V2 is the final volume of the solution.

Dilution is a fundamental concept in chemistry and is often used in various applications, from scientific experiments to everyday scenarios like making a refreshing lemonade. It allows us to control the strength or potency of a solution to meet specific requirements.

Concentration: The process of increasing the amount of solute in a solution.

Concentration, on the other hand, is the opposite of dilution. It involves increasing the amount of solute in a solution, typically by adding more of the solute substance or removing some of the solvent. Concentrated solutions have a higher solute-to-solvent ratio, making them potent and suitable for various purposes.

Concentration can be calculated using the formula:

Concentration (C) = (Amount of Solute) / (Volume of Solvent)

This equation expresses the concentration as the ratio of the amount of solute to the volume of solvent in the solution. Concentrated solutions are prevalent in fields like chemistry, biology, and industry, where precise control of solute content is critical.

Now that we have a clear understanding of what dilution and concentration entail, let’s delve into their purposes and applications.

2. Purpose and Applications

Dilution: Why and when do we dilute solutions?

Dilution serves several essential purposes in various fields:

- Experimental Control: In scientific research, researchers often need to create solutions with specific concentrations to carry out experiments. Dilution allows them to fine-tune the concentration to achieve desired outcomes.

- Medicine Preparation: In the healthcare sector, medications are frequently prepared as concentrated stock solutions and then diluted to provide the appropriate dosage to patients, taking into account factors like age and weight.

- Food and Beverage Industry: Dilution is employed in the production of beverages, such as fruit juices and soft drinks, to adjust flavor intensity and sweetness to consumer preferences.

- Analytical Chemistry: Dilution is crucial in analytical chemistry when analyzing substances in a sample. By diluting a sample, analysts can ensure that the concentration falls within the detection limits of the instruments used.

- Environmental Testing: Dilution is used in environmental testing to measure pollutant concentrations in water and soil samples accurately.

Concentration: When is concentration essential, and how is it achieved?

Concentration, on the other hand, finds its importance in various applications where having a potent solution is necessary:

- Chemical Reactions: In chemical synthesis, concentrated solutions are often required to drive reactions to completion or achieve higher reaction rates. Concentrated acids and bases are examples of reagents used in this context.

- Biotechnology: In biotechnology and molecular biology, concentrated solutions of enzymes, buffers, and DNA are used to carry out various laboratory procedures, such as PCR (polymerase chain reaction) and DNA sequencing.

- Food Preservation: Concentrated brine solutions are used in pickling to preserve vegetables and fruits by inhibiting the growth of spoilage microorganisms.

- Cleaning Products: Many household and industrial cleaning products, such as detergents and disinfectants, are sold in concentrated forms, allowing consumers to dilute them as needed for specific cleaning tasks.

- Mining and Metallurgy: In the mining and metallurgical industries, concentrated solutions are employed in the extraction of minerals and metals from ores.

Now that we’ve explored the purposes and applications of both dilution and concentration, let’s move on to the methods used to achieve these processes.

3. Methods of Dilution and Concentration

Dilution Methods: Techniques for reducing solute concentration

Diluting a solution is a common practice, and several methods can be employed to achieve this:

1. Volumetric Dilution:

- Description: This is the most straightforward method of dilution, where a known volume of a concentrated solution is added to a container, and solvent is added to reach the desired final volume.

- Use Cases: Commonly used in laboratories and industries when precise control of dilution is required.

2. Serial Dilution:

- Description: Serial dilution involves a series of dilutions, typically halving the concentration at each step. It is often used to create a range of dilutions from a single concentrated solution.

- Use Cases: Frequently employed in microbiology for microbial counting and in analytical chemistry for creating calibration curves.

3. Dilution by Weight:

- Description: In this method, the solute is weighed, and a specific quantity is dissolved in a known volume of solvent. The resulting solution’s concentration is determined by the weight-to-volume ratio.

- Use Cases: Used in situations where measuring by weight is more accurate than volume, such as in pharmaceutical compounding.

4. Dilution by Molarity:

- Description: Dilution by molarity involves calculating the amount of solute needed to achieve a desired molarity in a given volume of solution. It requires knowledge of the initial and final molarity.

- Use Cases: Common in analytical chemistry when working with solutions of known molarity.

5. Dilution by Serial Transfer:

- Description: This method involves transferring a portion of a concentrated solution to another container and diluting it further. It is commonly used in microbiology for bacterial culture dilutions.

- Use Cases: Vital in laboratories for preparing solutions with varying concentrations.

Now, let’s explore the methods used to achieve concentration.

Concentration Methods: Strategies for increasing solute concentration

Concentration is the process of making a solution more potent by increasing the amount of solute. Several methods are employed to achieve this:

1. Evaporation:

- Description: Evaporation involves heating a solution to vaporize the solvent, leaving behind a more concentrated solute. It’s a simple and effective method for concentrating solutions.

2. Crystallization:

- Description: Crystallization is a process in which a solution is allowed to cool slowly, causing the solute to crystallize and separate from the solvent. The remaining solution becomes more concentrated.

3. Reverse Osmosis:

- Description: Reverse osmosis is a membrane filtration process that removes solvent molecules, leaving behind a concentrated solute solution. It’s commonly used for desalination and water purification.

4. Centrifugation:

- Description: Centrifugation is often used to concentrate biological samples. By spinning the sample at high speeds, the denser solute particles are forced to the bottom, allowing for the removal of excess solvent.

5. Freeze Concentration:

- Description: In freeze concentration, a solution is frozen, and the ice crystals are separated from the concentrated liquid. This method is used in the food industry to concentrate fruit juices.

These methods allow for the precise control of solution concentration, depending on the desired outcome and the properties of the solute and solvent involved.

4. Calculations and Formulas

Dilution Calculations: How to calculate the final concentration after dilution

Dilution calculations are essential to ensure that the desired concentration is achieved. The most commonly used formula for dilution calculations is:

C1V1 = C2V2

Where:

- C1 is the initial concentration of the solution (before dilution).

- V1 is the initial volume of the solution (before dilution).

- C2 is the final concentration of the solution (after dilution).

- V2 is the final volume of the solution (after dilution).

This formula is used when a known volume and concentration of a solution (C1 and V1) are mixed with solvent to reach a desired final volume (V2) with the desired concentration (C2).

Concentration Calculations: Determining the concentration of a solution

Calculating the concentration of a solution is crucial for various applications. The formula for concentration calculations is:

Concentration (C) = (Amount of Solute) / (Volume of Solvent)

This formula expresses the concentration as the ratio of the amount of solute to the volume of solvent. The resulting concentration can be expressed in various units, such as molarity (M), percent (%), or parts per million (ppm), depending on the context.

To calculate concentration, you need to know the amount of solute and the volume of solvent in the solution. Once these values are determined, you can use the formula to find the concentration.

Now that we’ve covered the calculations involved in both dilution and concentration, let’s explore some practical examples in real life where these concepts are applied.

5. Examples in Real Life

Dilution in Medicine: How medications are prepared for patients

Dilution plays a crucial role in the field of medicine, particularly in pharmacy and patient care. Medications are often manufactured as concentrated solutions or powders, which are diluted to provide the appropriate dosage to patients. Let’s take a closer look at how dilution is applied in the medical field:

Medication Preparation:

- Scenario: A pharmacy receives a prescription for a patient who needs a specific dosage of a medication. However, the medication is only available in a concentrated form that is too potent for the required dosage.

- Solution: The pharmacist calculates the amount of the concentrated medication needed to achieve the prescribed dosage, considering the patient’s age, weight, and medical history. They then dilute the concentrated medication with a suitable solvent to reach the desired concentration for the patient.

Intravenous (IV) Solutions:

- Scenario: In a hospital, patients may require IV fluids for various medical conditions. These IV fluids, such as saline solutions, are prepared as concentrated solutions.

- Solution: Nurses and medical professionals dilute the concentrated IV solution with sterile water or saline to create solutions with the appropriate electrolyte concentrations for patient hydration and treatment.

Pediatric Medications:

- Scenario: Pediatric patients often require smaller doses of medication compared to adults. To ensure accurate dosing and minimize the risk of adverse effects, pediatric medications are often prepared as concentrated solutions.

- Solution: Pharmacists or nurses dilute these concentrated medications to create pediatric-friendly formulations with lower concentrations suitable for children.

Concentration in Food Industry: Enhancing flavors and preserving foods

Concentration is a vital process in the food industry, where it is used to enhance flavors, extend shelf life, and create various food products. Here are some examples of how concentration is applied in the food industry:

Fruit Juice Concentration:

- Scenario: Fruit juices are often concentrated to reduce volume and increase the shelf life of the product. Concentrated juice can be reconstituted with water before consumption.

- Solution: Freshly squeezed fruit juice is heated to remove a significant portion of its water content, leaving a concentrated juice. This concentrated juice is then packaged and sold to consumers, who dilute it by adding water to achieve the desired taste and consistency.

Soup and Sauce Concentration:

- Scenario: In food production, soups, sauces, and broths are often prepared in large quantities and concentrated to save storage space and transportation costs.

- Solution: The excess water is removed from the soups or sauces through processes like evaporation or freeze concentration. When ready to use, these concentrated products are diluted with water or other ingredients to restore their original consistency and flavor.

Concentrated Flavor Extracts:

- Scenario: The food industry relies on concentrated flavor extracts for various products, such as candies, beverages, and baked goods.

- Solution: Flavor extracts are produced by concentrating the natural flavor compounds from fruits, herbs, or spices. These concentrated extracts are used in minimal quantities to impart intense flavors to food and beverages.

6. Common Misconceptions

Dilution Misconceptions: Debunking myths about dilution

Misconceptions about dilution are not uncommon, and it’s essential to clarify some of the most prevalent ones:

Misconception 1: “Dilution Always Weakens a Solution.”

- Clarification: While dilution generally reduces the concentration of a solution, it doesn’t necessarily make it weaker. The term “weaker” depends on the specific context. In some cases, a more dilute solution may be precisely what is needed to achieve a desired outcome.

Misconception 2: “Dilution Eliminates the Effects of a Substance.”

- Clarification: Dilution can reduce the intensity of a substance’s effects, but it doesn’t eliminate them entirely. Some substances can still have significant effects even when highly diluted. This concept is central to homeopathy, where highly diluted solutions are believed to retain therapeutic properties.

Concentration Misconceptions: Clarifying misconceptions about concentration

Misunderstandings about concentration can also arise, and it’s important to address them:

Misconception 1: “Concentration Always Means a Stronger Solution.”

- Clarification: While concentrated solutions are often stronger in terms of solute content, this doesn’t necessarily mean they are more effective or better. The strength and effectiveness of a solution depend on its specific purpose and the properties of the solute and solvent.

Misconception 2: “Concentrated Solutions Are Always Harmful.”

- Clarification: Concentrated solutions can indeed be dangerous if mishandled, especially when dealing with hazardous chemicals. However, many concentrated solutions are essential for various applications and are safe when used as intended. Proper handling and dilution are key to ensuring safety.

7. Practical Tips for Dilution and Concentration

Now that we have a comprehensive understanding of dilution and concentration, let’s explore some practical tips for effectively utilizing these processes in various situations.

Dilution Tips

1. Use Proper Equipment

When performing dilutions in a laboratory or industrial setting, ensure you use the appropriate glassware or equipment designed for accurate volume measurements. Graduated cylinders, pipettes, and burettes are examples of instruments that help achieve precise dilutions.

2. Follow Protocols and Procedures

In scientific research and quality control, adhering to standardized protocols and procedures is crucial. Deviating from established methods can lead to inaccurate results. Always double-check the dilution steps outlined in your protocol.

3. Record Your Actions

Maintain detailed records of the dilution process, including the initial concentrations, volumes used, and final concentrations achieved. This documentation is essential for quality assurance, troubleshooting, and replicating experiments.

4. Be Mindful of Contamination

To avoid contamination, ensure that all equipment and containers are clean and properly rinsed before use. Contamination can lead to inaccurate results and compromise the integrity of your solution.

5. Safety First

When working with concentrated solutions, especially hazardous chemicals, prioritize safety. Wear appropriate personal protective equipment (PPE), work in a well-ventilated area, and follow safety guidelines and protocols.

Concentration Tips

1. Monitor Temperature

When concentrating solutions through methods like evaporation, be aware of temperature variations. Temperature can impact the rate of evaporation and the final concentration. Control and monitor temperature to achieve consistent results.

2. Consider Solvent Choice

The choice of solvent can significantly affect the concentration process. Some solvents may evaporate more readily than others, impacting the concentration rate. Choose solvents that are appropriate for your specific application.

3. Use Specialized Equipment

For industrial-scale concentration processes, specialized equipment such as rotary evaporators, freeze concentrators, and centrifuges can streamline the process and ensure precise control over concentration levels.

4. Maintain Hygiene in Food Industry

In the food industry, maintaining hygiene during concentration processes is crucial to prevent contamination. Ensure that equipment and facilities are clean and adhere to food safety regulations.

5. Test for Quality

Before packaging or using a concentrated product, perform quality tests to verify that it meets the desired standards. This is especially important in industries like food and pharmaceuticals, where product quality is paramount.

8. Future Trends and Innovations

The fields of dilution and concentration continue to evolve, driven by advances in technology and changing industry demands. Here are some future trends and innovations to watch for:

1. Nanotechnology in Concentration

Nanotechnology is increasingly being employed to achieve ultra-high concentrations of substances. Nanostructures and nanoparticles allow for precise control over the arrangement of molecules, leading to innovations in drug delivery, electronics, and materials science.

2. Green and Sustainable Processes

As environmental concerns grow, there is a push for more sustainable concentration and dilution processes. This includes the development of eco-friendly solvents, energy-efficient concentration techniques, and reduced waste generation.

3. Automation and Robotics

Laboratories and industries are adopting automation and robotics for dilution and concentration processes. Automated systems can perform repetitive tasks with high precision, reducing human error and increasing efficiency.

4. Point-of-Care Dilution Devices

In healthcare, point-of-care devices for dilution are becoming more advanced. These devices enable healthcare professionals to prepare medications with precision at the patient’s bedside, improving safety and dosage accuracy.

5. Advanced Analytical Techniques

In analytical chemistry, the development of advanced analytical techniques allows for more accurate and rapid concentration measurements. This includes techniques like mass spectrometry and nuclear magnetic resonance (NMR) spectroscopy.

As technology continues to advance and our understanding of chemistry deepens, the fields of dilution and concentration will undoubtedly see exciting developments and innovations.

Dilution or Concentration: Which One is Right to Choose?

Dilution and concentration are two fundamental processes in chemistry and various industries, each serving distinct purposes. Choosing between them depends on your specific goals and requirements. In this guide, we will help you determine whether dilution or concentration is the right choice for your needs.

When to Choose Dilution

Dilution involves reducing the concentration of a solution by adding more solvent. Here are scenarios where dilution is the preferred choice:

1. Safety Considerations:

- When working with hazardous substances: Dilution can reduce the potency of dangerous chemicals, making them safer to handle.

2. Precision Requirements:

- In scientific experiments: Dilution allows for precise control over solution concentrations, ensuring accurate results.

- In healthcare: Medications are often prepared as concentrated solutions and diluted to provide precise dosages tailored to individual patients.

3. Meeting Specific Requirements:

- In the food and beverage industry: Dilution is used to adjust flavors and sweetness to meet consumer preferences.

- In environmental testing: Dilution is employed to measure pollutant concentrations within the detection limits of instruments.

4. Creating Intermediate Concentrations:

- In microbiology: Serial dilutions are used to create a range of concentrations for microbial counting and experiments.

- In analytical chemistry: Dilution helps create calibration curves with varying concentration levels.

When to Choose Concentration

Concentration involves increasing the amount of solute in a solution. Here are scenarios where concentration is the preferred choice:

1. Enhancing Reactions:

- In chemical synthesis: Concentrated solutions are used to drive reactions to completion or achieve higher reaction rates.

- In biotechnology: Concentrated solutions of enzymes, buffers, and DNA are used in various laboratory procedures.

2. Food Preservation:

- In the food industry: Concentrated brine solutions are used to preserve vegetables and fruits by inhibiting spoilage microorganisms.

- In the production of sauces and soups: Concentration reduces volume for storage and transportation.

3. Industrial Processes:

- In mining and metallurgy: Concentrated solutions are crucial for the extraction of minerals and metals from ores.

- In cleaning products: Concentrated detergents and disinfectants are diluted as needed for specific cleaning tasks.

4. Creating Potent Products:

- In the pharmaceutical industry: Concentrated drug solutions are diluted to create medications with precise dosages.

- In the production of flavor extracts: Concentrated extracts are used to impart intense flavors to food and beverages.

Considerations for Your Decision

When deciding between dilution and concentration, consider the following factors:

- Type of Solution: Determine whether your solution needs to be made stronger or weaker in terms of solute content.

- Safety: If safety is a concern due to hazardous substances, dilution may be the safer choice.

- Precision: In situations requiring precise control, such as scientific research or healthcare, dilution is often preferred.

- Purpose: Think about the intended purpose of the solution. Is it for chemical reactions, preservation, or customization of flavors?

- Equipment: Consider the equipment available for the process. Some methods of concentration or dilution may require specialized equipment.

- Environmental Impact: In today’s environmentally conscious world, consider the environmental impact of your choice, including waste generation and energy use.

In conclusion, the decision between dilution and concentration hinges on your specific needs and goals. Both processes are valuable tools in various fields, offering the flexibility to tailor solutions to meet desired outcomes. Understanding their differences and applications empowers you to make informed choices, whether you’re conducting experiments in a laboratory, preparing medications for patients, or creating culinary delights in the kitchen.

FAQs

Dilution is the process of reducing the concentration of a solution by adding more solvent. This results in a decrease in the amount of solute per unit volume while maintaining the total amount of solute constant.

Concentration is the process of increasing the amount of solute in a solution. It involves making a solution more potent by adding more of the solute substance or removing some of the solvent.

Dilution is commonly employed when precise control over solution concentration is required, for safety reasons when dealing with hazardous substances, or to meet specific requirements in scientific experiments, healthcare, and environmental testing.

Concentration is often chosen when the goal is to enhance chemical reactions, preserve food products, increase solution potency, or create concentrated extracts for various applications, including the pharmaceutical and food industries.

Common methods of dilution include volumetric dilution, serial dilution, dilution by weight, dilution by molarity, and dilution by serial transfer.

Concentration methods include evaporation, crystallization, reverse osmosis, centrifugation, and freeze concentration, among others.

Dilution is evident in scenarios such as medication preparation in healthcare, adjusting flavors in the food and beverage industry, and environmental testing to measure pollutant concentrations accurately.

Concentration is widely used in chemical synthesis, food preservation, industrial processes, pharmaceuticals, and the production of concentrated flavor extracts.

The choice depends on factors like the type of solution, safety considerations, precision requirements, purpose, available equipment, and environmental impact. Each process has its unique applications and advantages.

Concentrated solutions may require careful handling due to their potency. Safety precautions, such as wearing appropriate personal protective equipment, are essential to minimize risks.

Read More:

Contents